Aerobic cleaning of the filtrate-digestate

Aerobic cleaning of the filtrate-digestate

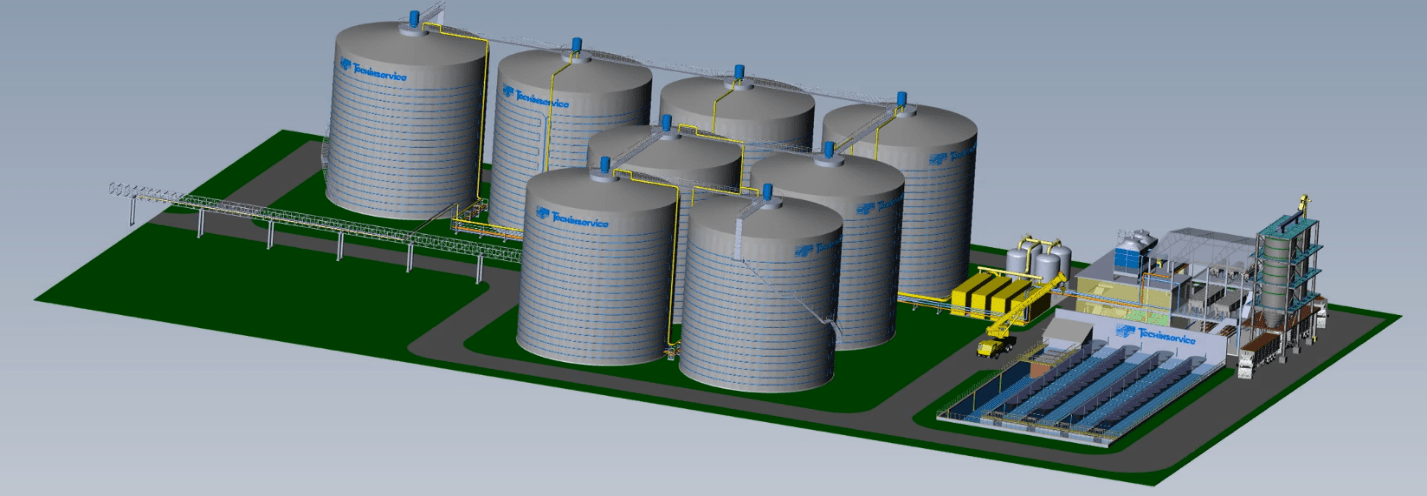

Technological process of aerobic digestate filtrate treatment.

The proposed scheme of aerobic water treatment allows obtaining water of conditionally purified quality with low chemical oxygen consumption, which can be used in the technological process.

After the decanter centrifuge, the filtrate is mixed in the collector and pumped together with excess active aerobic sludge through a tubular heat exchanger with the addition of coagulant and flocculant. The flocculated filtrate is fed to the flotator where it is separated into water clarified from suspended solids and flotation sludge from the surface and bottom of the flotator. The flotation sludge is discharged into a sludge collection tank, from where it is pumped to the decanter centrifuge for dewatering.

After preliminary treatment in the flotation tank, the clarified filtrate is fed through spray nozzles to the nitrification zone, where biological treatment takes place - in the aerobic reactor (aeration tank), ammonium nitrogen and organic contaminants are oxidised by activated sludge. The air is supplied to the aeration tank from the blower station and distributed by a system of diffusers, which allows for even air distribution and active mixing. To increase the contact surface, up to 45% of the aeration tank volume is loaded with MBBR nozzles. After the aeration tank, the biologically treated filtrate enters the membrane reactor where it is separated into water and activated sludge. The membrane reactor is based on the synthesis of biotechnology and technology for the separation of aqueous suspensions on polymeric membranes. The membrane reactor in the MBR system operates with a high concentration of activated sludge.

The microorganisms of activated sludge do not pass through the ultrafiltration membrane of the membrane reactor, so the treated water does not contain any microorganisms and is bacteriologically safe.

After the aerobic treatment unit, the water is fed to the final filtration and used in the technology of alcohol production, preparation of reagent solutions and CIP.

years experience in the development of production projects

successful projects of different scale in Ukraine and abroad

Representative offices in Bulgaria, Czech Republic