Biodiesel production

Biodiesel production

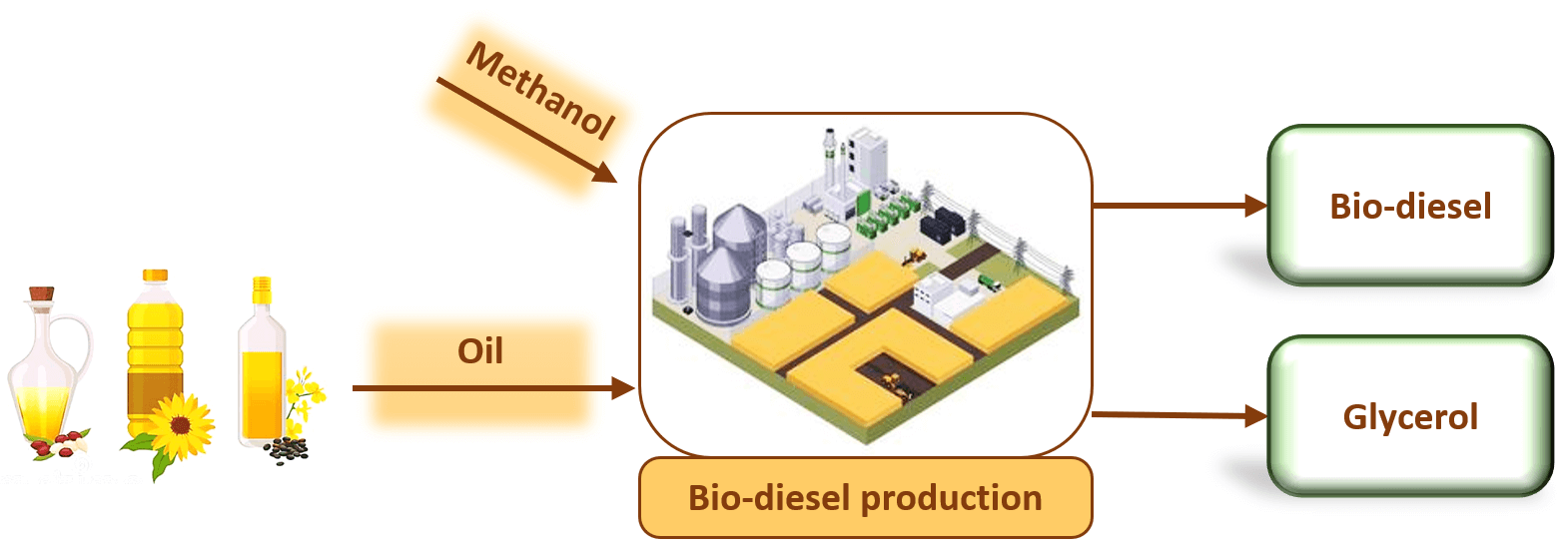

Biodiesel is a multi-component liquid fuel consisting of alcohol esters. The raw material for biodiesel production is vegetable oil. Biodiesel production technology is based on the catalytic transesterification reaction of vegetable oil in the presence of excess methanol. Sodium methoxide is used as a catalyst. The catalyst converts vegetable oil into a mixture of methyl esters.

The process consists of the following main steps:

- transesterification reaction;

- separation of the essential and glycerin fractions;

- separation of recycled methanol and glycerin;

- washing and purification of biodiesel;

- dehydration of biodiesel.

The construction area of the technological site is 20x20 m.

It consists of:

- reactor column;

- methanol regeneration and glycerin dehydration columns;

- biodiesel dehydration column;

- sanitary scrubber.

Separators with gravity passage between the reactors are located in a multi-storeyed stack.

years experience in the development of production projects

successful projects of different scale in Ukraine and abroad

Representative offices in Bulgaria, Czech Republic