Biogas purification – production of biomethane

Biogas purification – production of biomethane

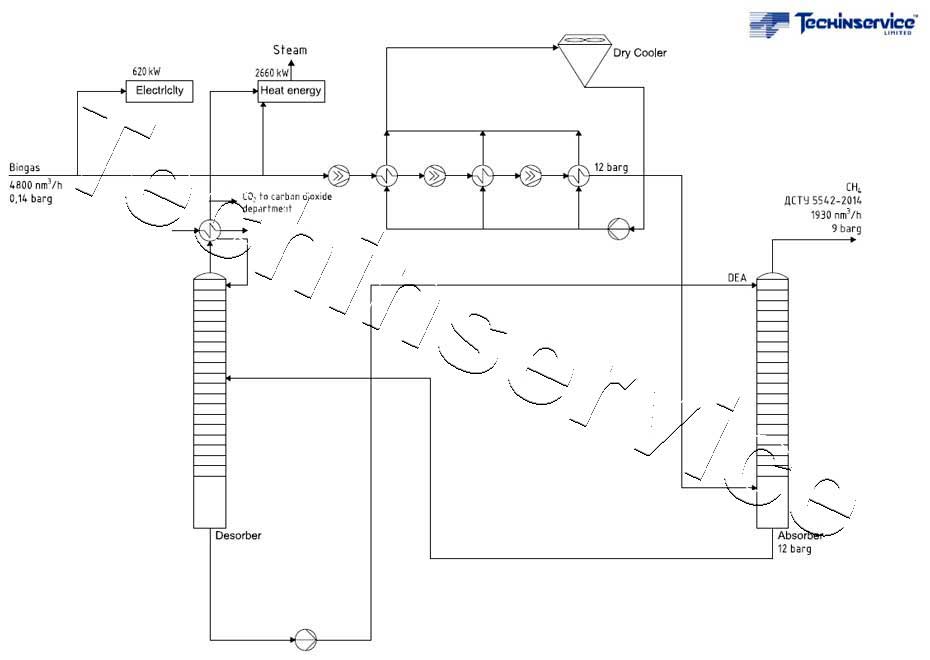

The scheme of biogas purification in accordance with the normative value of DSTU 5542-2014 includes self-absorption of doses using solvent activity of diethanolamine. Biogas after the biogas plant is cleaned of H2S removal, compressed on the compressor unit to a pressure of approximately 15% more than necessary for further return in the gas transmission network, and fed to the absorption. For the additional solvent, biogas is broken down into methane CH4 and CO2 with impurities that are absorbed by diethanolamine. Purified methane is absorbed by an automatic mixer and sent to the gas mixture. The solvent, saturated with CO2 and impurities, is absorbed to the desorption column, reduced and re-fed to the absorber. The carbon dioxide seen in the desorption colony is transported to the treatment and incineration plant.

The process is characterized by the newest (among the known purification methods) methane output from primary biogas - 99.9%. Specific energy consumption for the cleaning process, without interrupting 0.1 kW/Nm3 of biogas. The specific consumption of thermal energy is not more than 0.5 kW/Nm3 of biogas, and can be reduced by integrating into the thermal circuit of a biogas plant and using residual heat.

To generate the necessary electrical and thermal energy for the purification process, the possible use of own biogas, or the withdrawal of these resources from other networks.

years experience in the development of production projects

successful projects of different scale in Ukraine and abroad

Representative offices in Bulgaria, Czech Republic