Articles

Reconstruction of Gaisyn Sugar Mill in 2012: increase of capacity and reduction of consumption of fuel equivalent

08.09.2014

Бондаренко Л.А., главный технолог Гайсинского сахарного завода ООО ПК «Зоря Поділля»

____________

В 2012 году Производственной группой «Техинсервис» была осуществлена реконструкция Гайсинского сахарного завода, ПК «Зоря Поділля», с целью увеличения производительности завода с 6000 тонн свеклы/сутки до 8000 тонн свеклы/сутки и уменьшения удельного расхода пара на производство до 28,5% к массе свеклы.

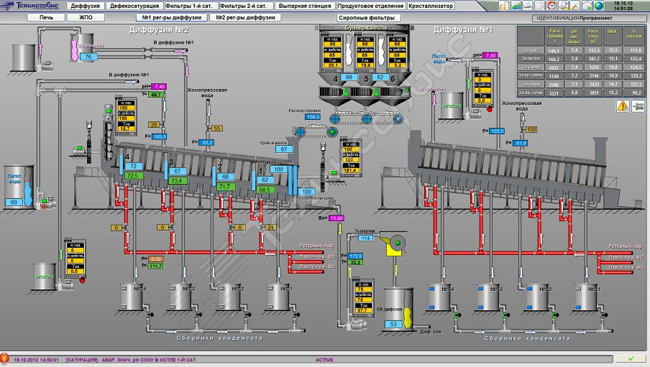

• The ДС-12 diffusion house installed in 2012 at the mill including beet cutters, chips feeding line, pulp discharge line, condensate collection and withdrawal line has been automated;

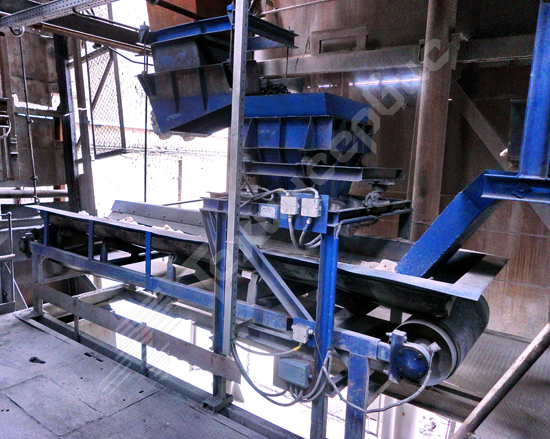

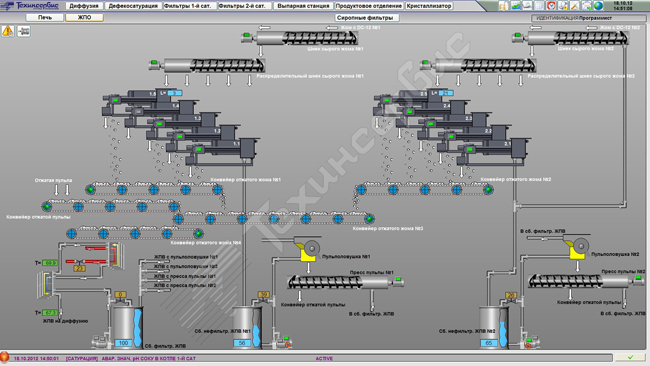

• Pulp-press house: pulp-press water pasteurization line has been installed; raw pulp feeding line and pressed pulp discharge lines have been automated.

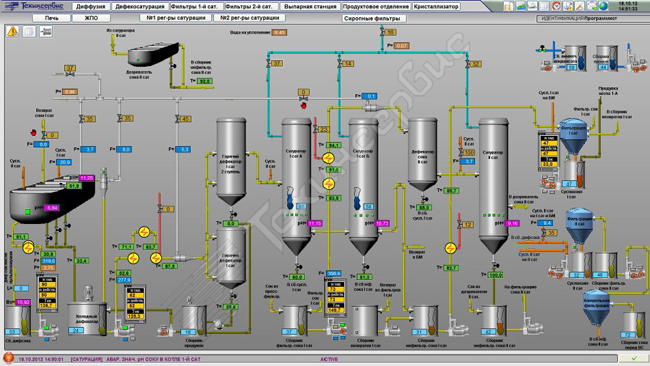

• Juice purification station: following equipment produced by Techinservice was installed – Briegel-Muller progressive prelimer (designed for a capacity of 10,000 tons of beet/day), lime milk dynamic mixer and 2nd carbonation tank. All main flow pumping units have been replaced by Andritz pumps with hydrodynamic sealing.

• Heating system and evaporating station: the quintuple-effect evaporating station was changed to the sextuple-effect evaporating station with the use of the existing Robert evaporators in the 1st, 2nd, 5th and 6th effects, as the 3rd and 4th effects the direct-flow fallingfilm evaporators of Series ТВП12-4870 and ТВП9-2430 were installed.

• Condensate circuit is fully assembled on the basis of new multisection condensate collectors produced by Techinservice.

- Pulp-press water: heat exchanger of Series ТТЖВ83 and heater of Series ТПЖВ83;

- Diffuse juice: low-grade steam heater of Series ТПДУ270 – 2 pcs.;

- Limed juice: heat exchanger of the 1st group of Series ТТДС244; heater of the 2nd group of Series ТПДС361; heater of the 3rd group of Series ТПДС244;

- Juice before 2nd carbonation: new plate heat exchangers of the 1st group (2 pcs.) have been installed and connected according to the parallel scheme; existing heaters of Series ПДС-10-200 have been connected according to the parallel scheme;

- Juice before the evaporating station: new baffle heater of the 4th group has been installed; 3rd, 2nd and 1st group were composed of existing heaters of Series ПДС-10-200, upgraded from 10-way heaters into 5-way heaters;

• Melting of brown sugar of the 2nd and 3rd products is carried out by syrup after the evaporating station in the melting mixers of Series TKM-30 and TKM-15 produced by Techinservice.

Magma seed receiving mixers

Detailed information is given below:

Mnemonic scheme of the diffusion house

Mnemonic scheme of the diffusion houseThe sterilization circuit of the pulp-press water (PPW) with the use of a rapid heat exchanger and a heater produced by Techinservice heats the water before sterilization and then cools it to a predetermined temperature (72-65 °C).

Mnemonic scheme of the pulp-press house

Mnemonic scheme of the pulp-press house1) The new Briegel-Muller progressive prelimer of Series ТППД200 which was mastered for production in 2012, was installed.

3) 1st carbonation boiler consists of 2 stages: 1st stage is the former 1st carbonation boiler; 2nd stage is the former 2nd carbonation boiler

4) Muddy juice tank is mounted on the basis of the former 2nd carbonation juice maturing tank.

Mnemonic scheme of the juice purification house

Mnemonic scheme of the juice purification house6) 2nd carbonation boiler: a new boiler of Series TC2-4.2 has been installed.

8) For better mixing of lime milk and juice, the following units have been installed: dynamic mixer in front of the cold liming tank; static mixers before the main liming and in front of the liming tank before the 2nd carbonation.

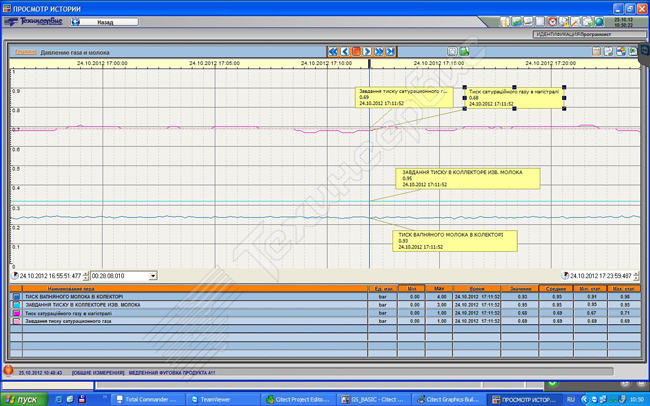

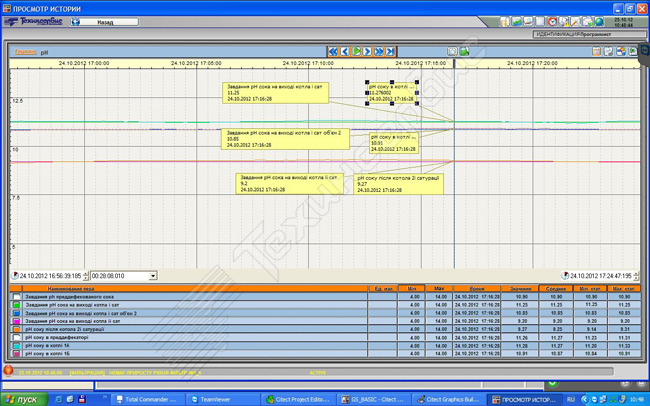

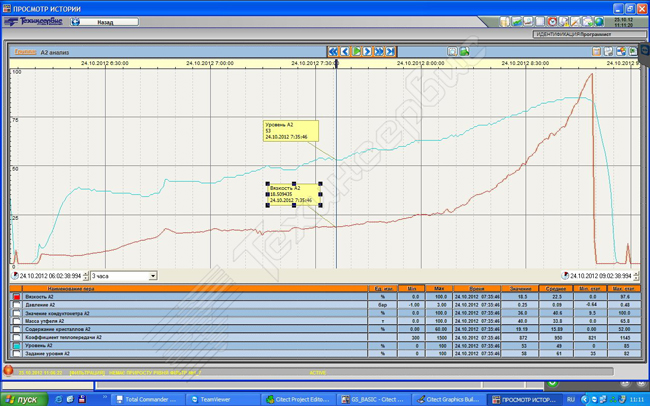

Juice purification trend

Juice purification trend Juice purification trend

Juice purification trendTechinservice automated two new 1st carbonation juice filters and one new 2nd carbonation juice filter installed by the sugar mill in 2012.

Heat of ammonia condensate is used for heating of runoffs of the sugar end, juice before the 2nd carbonation and limed juice. After cooling the ammonia condensate at the limed juice heat exchanger to a temperature of 68-72 °C, the condensate is distributed to the feed water tank for diffusion and the tank of other consumers. Condenser water is not used for feeding the diffusion units.

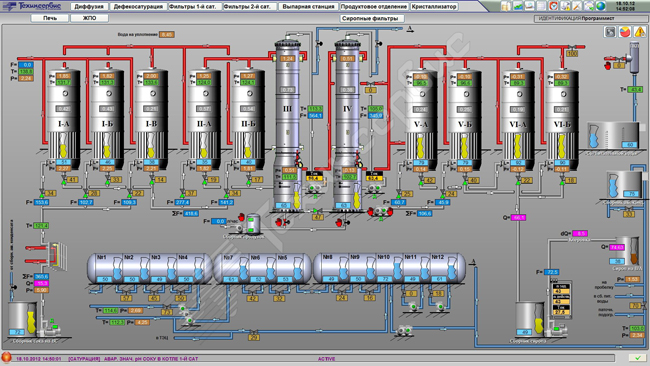

Mnemonic scheme of the evaporating station

Mnemonic scheme of the evaporating stationModernization of the heating scheme allowed achieving the steam consumption of 89 t/hour for a capacity of 8,000 tons of beet/day, consumption of fuel equivalent by weight of beet is 2.8% and by weight of sugar is 20.1%.

Filtering the syrup using five new TF150-65 filters with perlite alluvium produced by Techinservice allowed reducing the colour value of the syrup after the evaporating station by 3 times. At the same time, the quality of commercial sugar has significantly improved (haze was 8 icumsa).

The syrup can be filtered without perlite alluvium but in this case the used equipment should be of significantly more power.

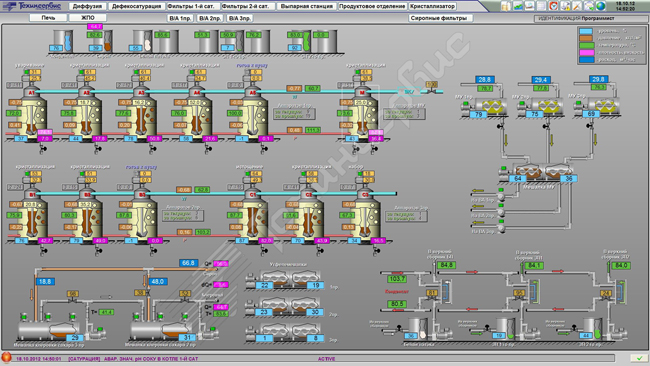

Mnemonic scheme of the sugar end

Mnemonic scheme of the sugar end Trend of the vacuum pan of the 1st product

Trend of the vacuum pan of the 1st product

Due to the implemented changes in the sugar end, the boiling time of the 1st product was 2.25-2.5 hours, the 2nd product was 3.5-4 hours and the 3rd product was 8-8.5 hours. The granulometric composition and colour value of commercial sugar have also been improved (colour value was 0.48 icumsa, average size was 0.79 mm, C.V. was 26.2%, haze was 8 icumsa).

A new fan cooling tower with an advanced spray system has been installed at the plant. This measure allowed for the maintenance of a stable temperature of chilled recirculating water, and accordingly rarefaction in the vacuum system without pumping river water.

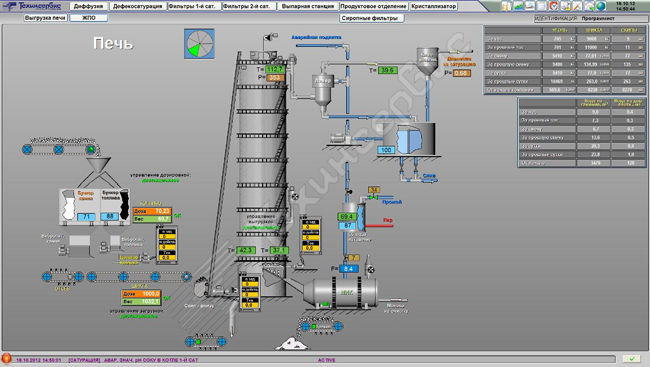

Mnemonic scheme of the limestone house

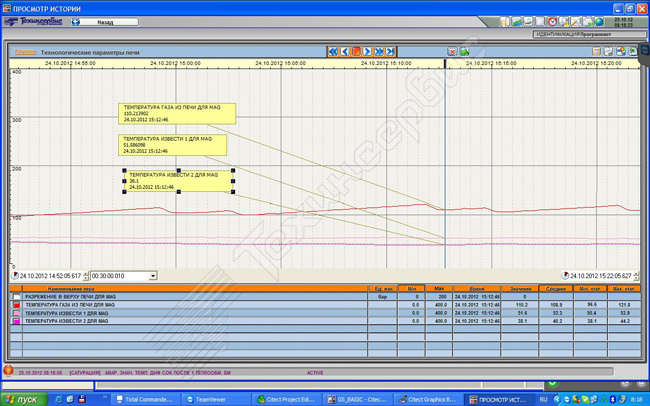

Mnemonic scheme of the limestone house Trend of the limestone house

Trend of the limestone house

| Parameter | Unit | |

| The capacity of the plant | tons of beets/day | 8000 |

| Consumption of fuel equivalent by weight of beet | % | 2,8 |

| Consumption of fuel equivalent by weight of sugar | % | 20,1 |

| Steam consumption for production | t/hour | 89 |

| Haze of commercial sugar | icumsa | 8 |

| Colour of commercial sugar | icumsa | 0,48 |

| Average size of sugar granules | мм | 0,79 |

| Consumption of limestone for production | % by weight of beet | 3,1 |

________________________________

Journal Sugar of Ukraine No.10, 2012