Press Centre

Внедрение системы автоматизации и диспетчеризации нового фармацевтического завода ЧАО «Биофарма»

23.12.2014

With over 20 years' experience in developing process automation and building management systems for various industries, Techinservice Intelligence has developed and implemented a comprehensive automation system with process control and building infrastructure management of a new pharmaceutical plant of With over 20 years' experience in process automation and building management systems for various industries, Techinservice Intelligence has developed and implemented a comprehensive automation system with process control and building infrastructure management of a new pharmaceutical plant of PJSC "Biopharma" (Bila Tserkva, Ukraine).

The building management and automation systems have been implemented in two buildings of the plant – the production building and laboratory building.

The building management and automation systems have been implemented in two buildings of the plant – the production building and laboratory building.

The building management system continuously collects information from primary sources (temperature and pressure sensors, etc.), displays it in a user-friendly form, archives and records abnormal deviations of parameters.

The automation system monitors and controls the technological areas of production as well as the life support areas of buildings.

The building management and automation system of a new mill of Biopharma Pharmaceutical Company includes several process areas:

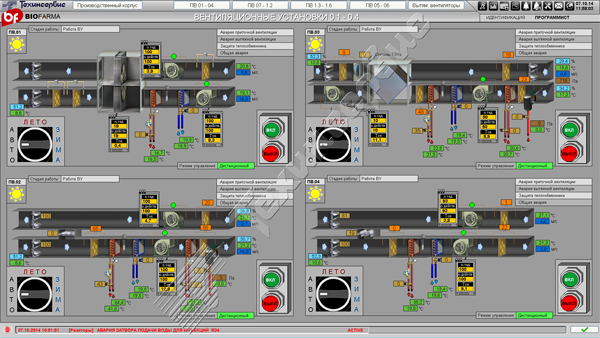

1. Ventilation and air conditioning system

It includes 14 air handling units of the production building and 11 air handling units of the laboratory building. Moreover, it includes 23 air exhausters of the buildings.

Mnemonic control scheme of the ventilation units

Mnemonic control scheme of the ventilation units

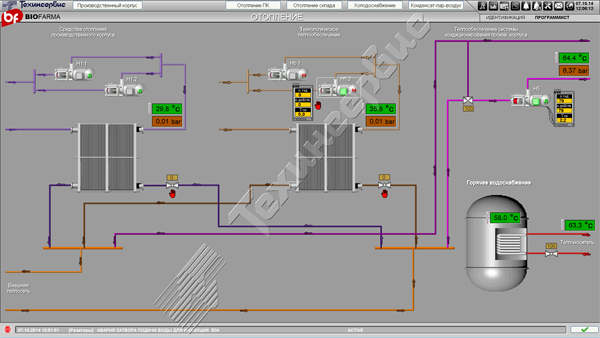

2. IHU (individual heating unit)

The automation system of an individual heating unit is designed to control the pumps feeding the heat transfer fluid to the heating, air conditioning and process heat supply systems and the operating mechanisms for maintenance of the specified temperature of the heat transfer fluid.

The heating units of the production building, laboratory building and warehouse of the plant are automated.

Mnemonic control scheme of the heating system

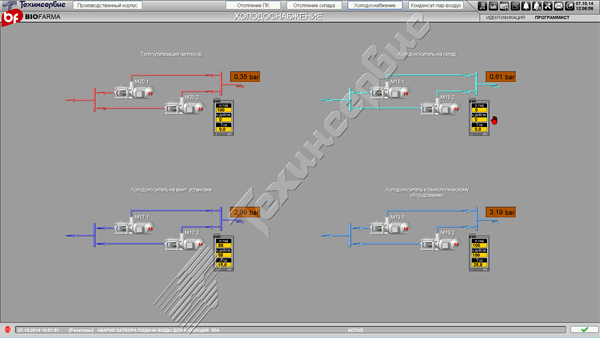

3. Refrigeration

The automation system of refrigeration systems ensures the specified pressure in the systems of cold supply to the process sections of the production facilities.

Mnemonic control scheme of the refrigeration system

Mnemonic control scheme of the refrigeration system

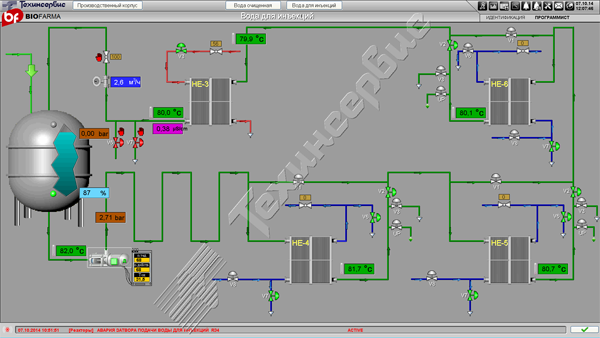

4. Water treatment

The automation system of water preparation for the production facilities controls the pumps feeding water to the circulation circuit, maintains the specified water temperature in the circulation circuit, controls make-up of water collection tank and water treatment for end consumers. An automation system of water for injection and purified water treatment has been implemented at this plant.

Mnemonic control scheme of the water for injection and purified water treatment

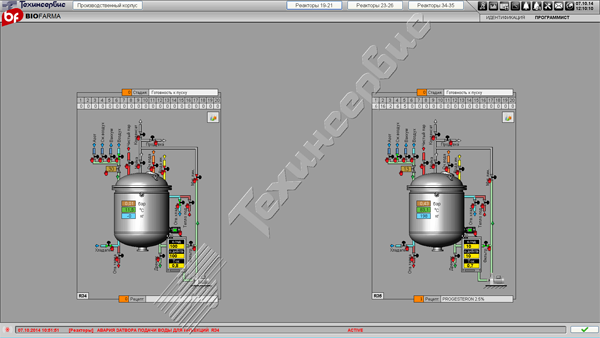

5. Reactors

The automation system of the reactors in which the pharmaceutical agents are mixed for obtaining the finished product is implemented at the plant. Feeding, mixing and discharge are carried out automatically by controlling the operating mechanisms. Feeding of products and mixing process are carried out according to the preset recipes.

Mnemonic control scheme of the reactors

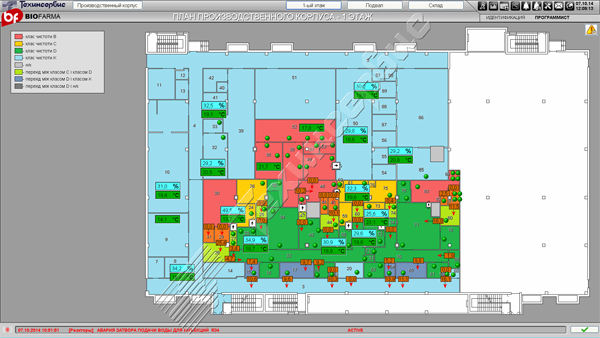

6. Microclimate

Control of temperature, humidity and pressure changes in clean areas of the production building and laboratory. The system gives alarm and pre-alarm messages if monitored parameters have passed the specified boundaries. Generation of daily reports.

Mnemonic control scheme of the microclimate system

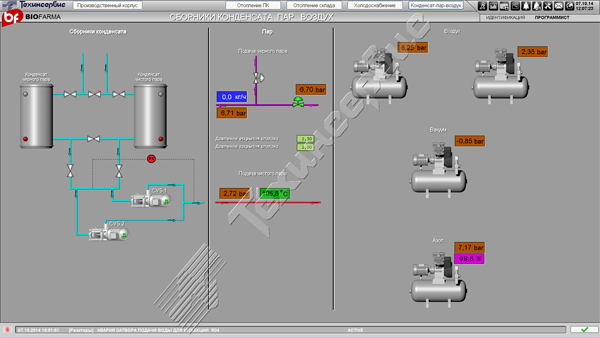

7. Air, vacuum, nitrogen

Control of the process parameters (pressure, rarefaction etc.) of a compressor station, vacuum pumps and steam from the boiler house.

Mnemonic control scheme of the process parameters of Biopharma Pharmaceutical Mill

The automation and building management system developed by Techinservice for the new mill of Biopharma Pharmaceutical Company guarantees the following economic advantages:

- energy savings (electricity, heat, water and gas);

- reduction of maintenance personnel;

- reduction of costs for maintenance, repair and replacement of the engineering equipment;

- reduction of damage from accidents due to their prevention and timely detection;

- increase of the service life of processing equipment by taking into account the time of operation and uniform use of its remaining life;

- reduction of costs under the service agreements due to minimization of work scope due to the constant control and recording of the parameters of the operating conditions of the equipment;

- improving the reliability of operation of the engineering systems of the building due to the use of automation equipment from a single vendor;

- possibility of expanding the system in future;

- possibility of combining several objects into a network;

- availability, ease of use, reduction of requirements for the technical level of staff;

- ability to meet the energy limits;

- prompt detection and malfunction repair;

- increase of comfort and safety levels