Projects

Bio-glue production plant.

08.01.2026

Exterior View of the Bio-Glue Production Workshop

Bio-glue

Following the completion of commissioning and start-up operations, the bio-glue production plant has been put into industrial operation.

The capacity of the implemented bio-glue production facility is 30,000 tons per year.

The main components used in the production of bio-glue are plant-based proteins (wheat, corn, rapeseed, peas, soybeans), water, and glycerin.

This facility ensures compliance with EU Regulation 2023/1464, which comes into effect on 6 August 2026. The regulation tightens the requirements for formaldehyde content in adhesive mixtures used by MDF and HDF panel manufacturers, as well as the woodworking industry. It establishes maximum allowable formaldehyde emission levels of 0.062 mg/m³ for furniture and 0.08 mg/m³ for other products.

The technology for the preparation and storage of bio-glue provides a fully closed cycle from the beginning of the technological process to its completion, ensured by a system of air ducts, pipelines, and tanks.

Tanks for Storing Finished Product and Protein Component

The adopted method for the preparation of bio-adhesive consists of the following stages:

-loading raw materials into pre-mixers;

-mixing components in pre-mixers with a capacity of 0.7 m³, with simultaneous cooling or heating;

-loading raw materials into a 4 m³ reactor;

-mixing components in the reactor with simultaneous cooling;

-adding components from the pre-mixers into the reactor;

-final mixing in the reactor under vacuum with simultaneous cooling;

-transferring the bio-glue into storage tanks of 2 × 100 m³;

-cleaning and rinsing the equipment.

Bio-Glue Transfer Rack to the Production Facility

The installation consists of the following sections:

-Component receiving and unloading unit

-Reagent storage

-Power supply unit (chiller, electric boiler)

-Technological unit (feeders, mixers, reactor)

-Bio-glue storage unit

Chiller Unit

During the creation of the bio-glue production facility, the following works were carried out:

-A complete set of design works was performed in accordance with DBN A.2.2-3-2014;

-The Environmental Impact Assessment (EIA) procedure and the state examination of the project documentation were completed;

-The required technological equipment made of stainless steel, developed by the in-house design department, was manufactured;

-An automatic control system with the necessary software was developed and manufactured;

-Supervision and installation work for the equipment and control system were carried out;

-Commissioning and start-up procedures were performed.

Bio-glue Production Plant

Cooling/Heating Circuit Equipment

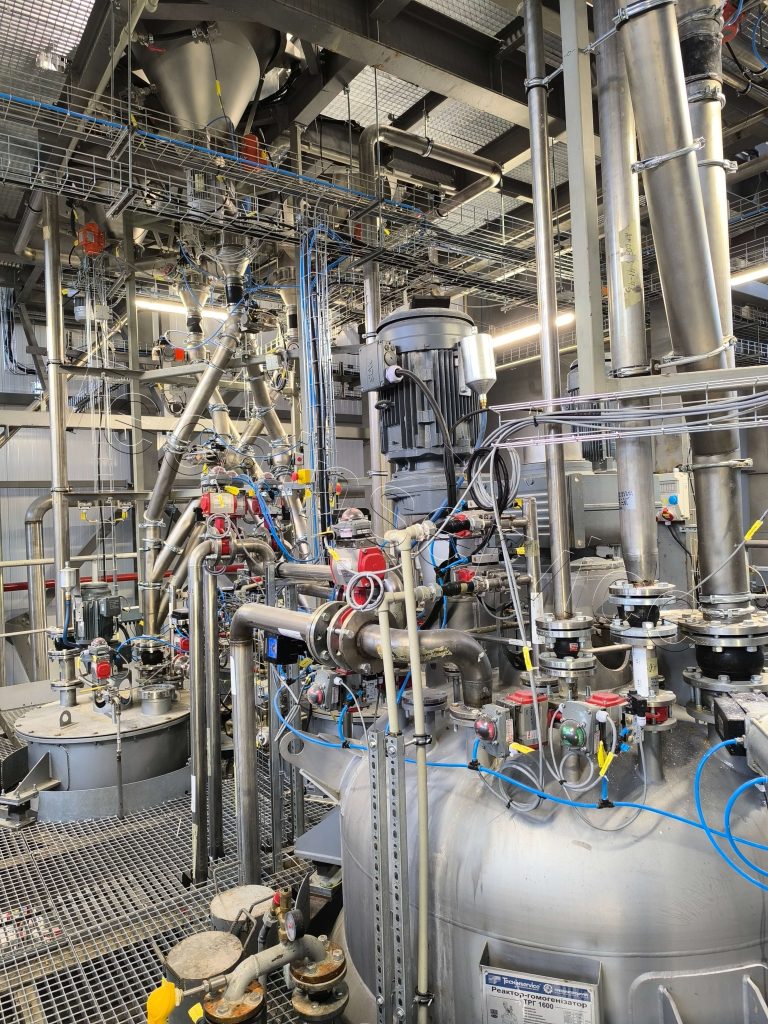

Reactor and Mixers

Completion of the installation of the Bio-glue production unit.

years experience in the development of production projects

successful projects of different scale in Ukraine and abroad

Representative offices in Bulgaria, Czech Republic