2015 Projects

First Batch of UF-Resin at Korosten MDF Plant (Ukraine)

22.10.2015

Techinservice Manufacturing Group implemented a turn-key project on construction of the urea-formaldehyde (UF) and melamine-urea-formaldehyde (MUF) resin production facility for Korosten MDF Plant. The facility production capacity is 150 tons per day.

Techinservice Manufacturing Group implemented a turn-key project on construction of the urea-formaldehyde (UF) and melamine-urea-formaldehyde (MUF) resin production facility for Korosten MDF Plant. The facility production capacity is 150 tons per day.

The whole production process is highly mechanized and automated at the state-of-the-art level, which results in strict compliance with preset recipes and high-quality and environmentally-friendly UF resin of classes E-1 and E-0.

The Complex consists of the following sections:

- section for unloading urea from hopper cars;

- urea storage;

- section for unloading urea-formaldehyde concentrate (UFC) from tank cars;

- UFC storage;

- UF resin storage;

- UF/MUF resin production section.

The Project has been accepted by relevant authorities and put into operation. The State Ecological Expertise Committee approved its full compliance with all international safety standards and effective technical guidelines. The turn-key project implementation period including start-up and commissioning works is 12 months.

It's worth noting that the entire scope of project design works was made by own Design Engineering Department, and all process equipment and steel structures for this production facility were manufactured by Grebenky Machine-Building Plant (GMZ), which is a part of Techinservice MG.

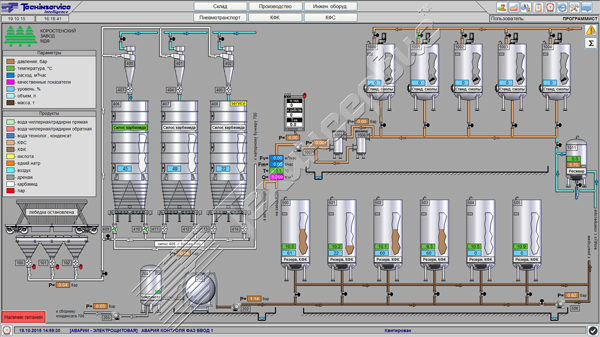

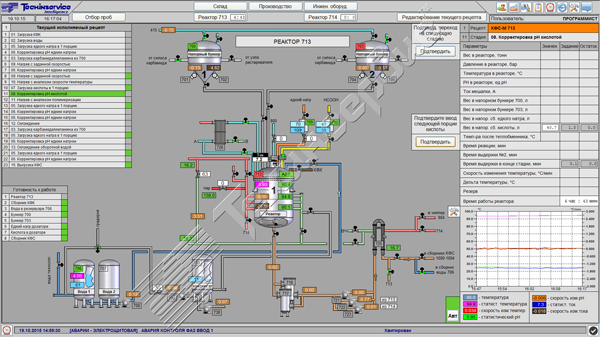

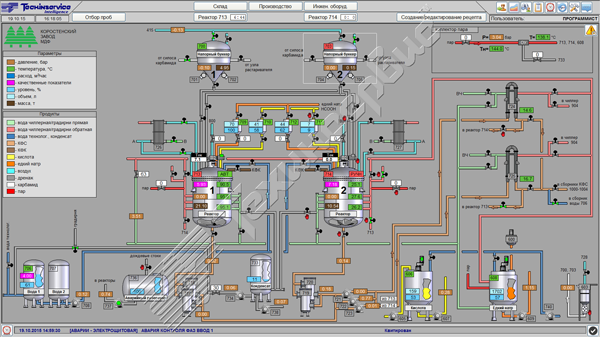

The automation engineering department Techinservice Intelligence has tailored an automatic control system called SimpleChemResin. This control system allows preparing UF resin of different recipes in fully automated mode.

Operator's Room of UF/MUF Resin Production Facility at Korosten MDF Plant

Operator's Room of UF/MUF Resin Production Facility at Korosten MDF Plant

Mnemonic Diagrams of SimpleChemResin Automatic Control System for Korosten MDF Plant

years experience in the development of production projects

successful projects of different scale in Ukraine and abroad

Representative offices in Bulgaria, Czech Republic