2010 Projects

Korosten MDF Manufactory (Ukraine)

04.12.2018

Since December 2008, Techinservice has been directly involved in the project to build the first and unique plant in Ukraine for the production of MDF and HDF panels.

The plant is designed to produce 900 m3 of MDF panels per day, which corresponds to the production output of about 300,000 m3/year.3/год.

For this project, Techinservice has manufactured and installed equipment for the following stages of manufacturing products that meet the most stringent European EN standards, as well as German DIN standards:

- barking, chip production

- chip washing

- preparation and manufacture of fiber

- fiber drying

- adhesive preparation and batching

- mechanical and pneumatic conveyors

- pneumatic means of transportation

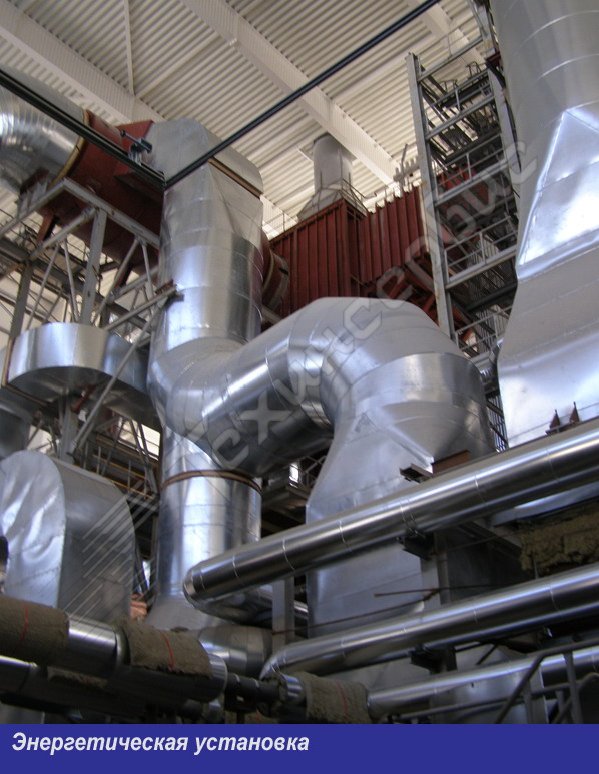

- power generating plant

- окоровка, изготовление щепы

Owing to its many years of experience, technical potential and the availability of highly qualified specialists, Techinservice also won the tender for the production and installation of all steel engineering structures of the plant with a total weight of 2,000 tons including:

- supporting metal structures

- handrails, ladders and platforms for the press

- cable racks

In addition, Techinservice is a prime contractor for installation of all processing equipment and metal structures at this facility.В частности были смонтированы:

In particular, the following equipment was mounted:

- barking drum with diameter of 6 m, length of 20 m, weight of 120 tons and with rotation speed of 96 rpm;

- forming and pressing line (a hot press – a so-called "the heart of the plant" with length of 100 m and weight of up to 1,000 tons);

- MDF panel cooler;

- grinding line;

- laminating line etc.

For reference: MDF is a material that is gradually replacing wood chipboard (DSP) and wood panel boards (DVP) in the furniture and building industries all over the world.

MDF (finely dispersed fraction of wood) is a medium-density fiberboard manufactured by pressing wood fiber. This material is produced in the form of panels made of dried wood fibers treated with special binders and further pressed in the hot press to the density of up to 700-870 kg/m3. MDF has good hydrophobic properties (water repellency), high environmental criteria and complies with the European Standard EN 622-5. Medium-density fiberboards can be used as a base for lamination, pasting, veneering and dyeing.

HDF is a high-density fiberboard. HDF is made of the same material and by the same method as MDF but with application of the higher pressing pressure. As a result, increased strength and hardness of material are achieved. It is used as the base of laminated flooring.

Ecology: Environmentally friendly production

years experience in the development of production projects

successful projects of different scale in Ukraine and abroad

Representative offices in Bulgaria, Czech Republic