2014 Projects

Sugar plant Nordzucker AG (Uelzen, Germany)

15.12.2014

Techinservice Manufacturing Group – is the only Ukrainian engineering and machine building company producing and selling quality equipment to the leading companies in the EU ’s sugar industry.

Equipment manufactured by “Techinservice MG” is successfully working in many European sugar plants in Bulgaria, Poland, Latvia, Lithuania, Slovakia, Serbia, Hungary and the Czech Republic.

Recent delivery of equipment manufactured by “Techinservice” to Germany has proven once more that Ukrainian company can compete on equal footing with the leading European equipment manufacturers in the sugar industry, globally expanding the geography of sales.

________________________________________________________________

Techinservice Manufacturing Group has completed the delivery and supervision installation of the low-grade steam preheater of the diffusion juice for a sugar plant in Uelzen town, owned by the largest sugar concern in Germany Nordzucker AG. Processing capacity of the factory is 22 000 tons of beet per day.

Our main advantage over all competitors – is the lowest possible underheating to the saturation temperature of the steam.

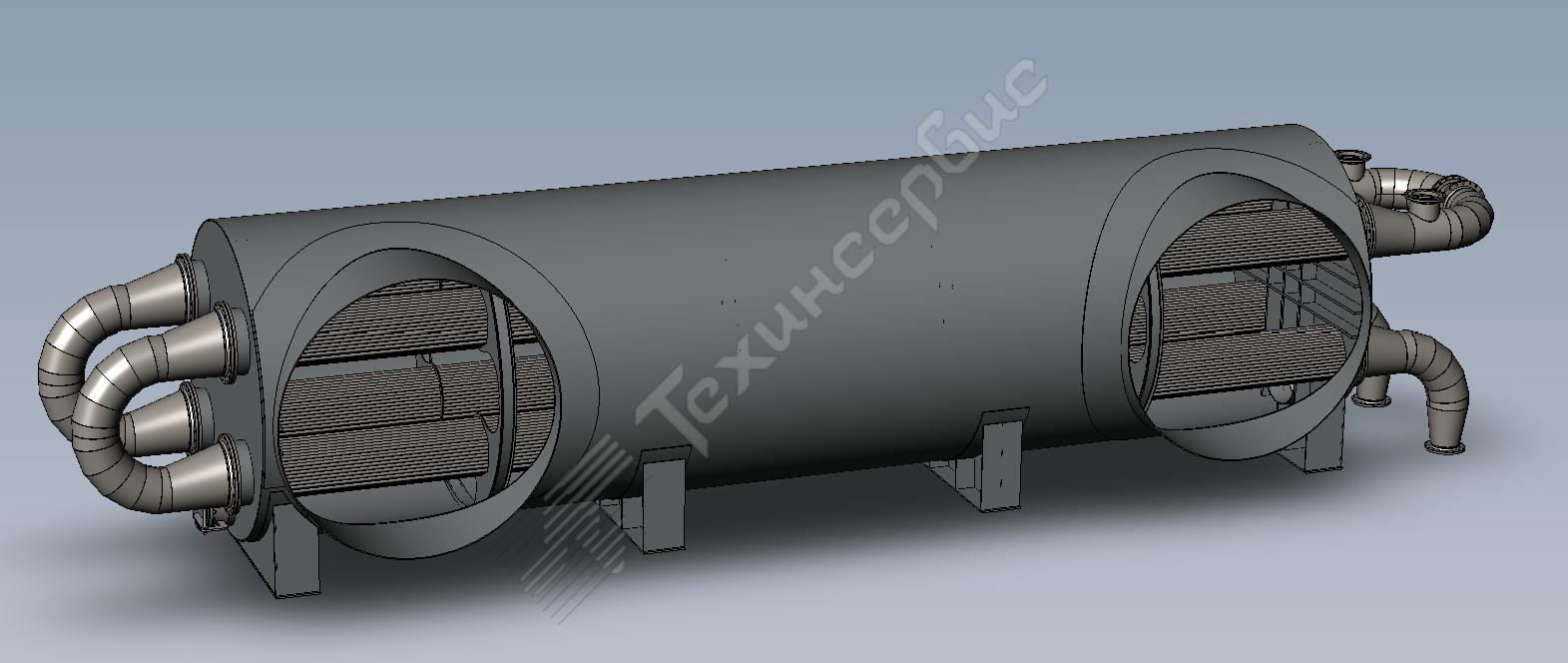

Low-grade steam preheater was manufactured as a single unit. Its total length is 17.8 meters; weight 43 tons.

3D-model of the low-grade steam preheater TPDU

3D-model of the low-grade steam preheater TPDU

Heat transfer area of the unit is 1236 m2.

Overall average performance indicators:

Payback period – first production campaign.

|

Diffusion juice: Consumption 817 m3/h, Inlet temperature: 25°C Outlet temperature: 48.8°C |

Steam: Pressure 0.15 bar Temperature 53.3°C |

Underheating to the saturation temperature of the steam is 4.5°C |

Time of development, fabrication and delivery including the specific requirements of the customer was two months.

Dispatch of the diffusion juice preheater from “Grebinki a machine-building factory”

Dispatch of the diffusion juice preheater from “Grebinki a machine-building factory”

Installation works were done under the strict supervision of the skilled professionals of “Techinservice Manufacturing Group”.

This low-grade steam preheater was mounted in one hour. Lift height – is 25 meters.

Installation of the low-grade steam preheater at site in Uelzen town, Germany

Installation of the low-grade steam preheater at site in Uelzen town, Germany

Mounted preheater of the diffusion juice

Mounted preheater of the diffusion juice

By installing the preheater of the diffusion juice from “Techinservice MG” the customer has received the following advantages:

- reduction of the overall heat consumption of the factory due to the utilization of low-grade steam coming from the Massecuite (secondary steam of vacuum pans).

- minimal calcification due to the high rate of flow and therefore reduction of maintenance works;

- Long operational life (more than 15 years) without major reconstruction due to the unique structure of the steam part, which ensures minimal destructive effect on the pipes.

- remote control, unit works without attendance.

The preheater was manufactured in accordance with all related regulations of European Union (CE) and Germany (AD2000) and certified by the International certification agency TÜV Rheinland.

Mounted preheater of the diffusion juice at the factory of Nordzucker AG

Mounted preheater of the diffusion juice at the factory of Nordzucker AG

Note: Sugar factory in Uelzen town belongs to German sugar giant “Nordzucker AG”, second biggest sugar producer in Europe. Named factory is the biggest factory of the group producing around 50% of the sugar Nordzucker supplies for retail.

Sugar plant of Nordzucker AG in Uelzen town, Germany

years experience in the development of production projects

successful projects of different scale in Ukraine and abroad

Representative offices in Bulgaria, Czech Republic