Boilers Transfer to CWFB

Boilers Transfer to CWFB

Conversion of boilers to coal-water fuel (CWF)

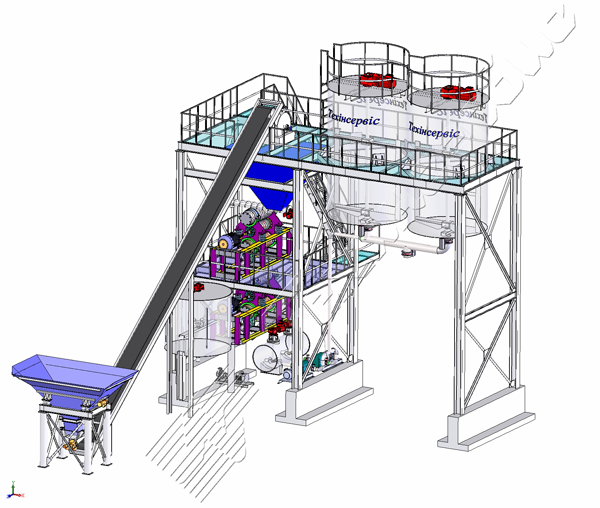

It is very efficient and economically feasible to convert small and large boilers to the CWF burning instead of liquid fuel and natural gas due to the constantly increasing prices for these types of fuel. CWF preparation station according to Techinservice technology

CWF preparation station according to Techinservice technology

The coal-water fuel (CWF) is a new generation of artificial composite fuel which is a dispersed fuel system consisting of micronized coal, water and a plasticizer reagent. It is produced from anthracite, stone and brown coal of any grade, coal sludge and water of any quality, including mine and industrial waters, as well as molasses alcohol dregs.

Techinservice MG has developed a completely waste-free and environmentally friendly technology for the preparation of coal-water fuel which is implemented by arranging individual units of necessary equipment, in particular:

- equipment for CWF transportation and storage

- equipment for grinding coal and obtaining CWF

- equipment for CWF homogenization and filtration

- equipment for CWF burning

Due to the ease of transportation of CWF, it is possible to construct a centralized facility for its preparation and to supply consumers with ready-made fuel.

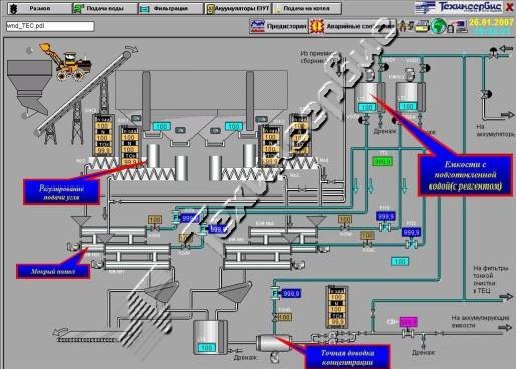

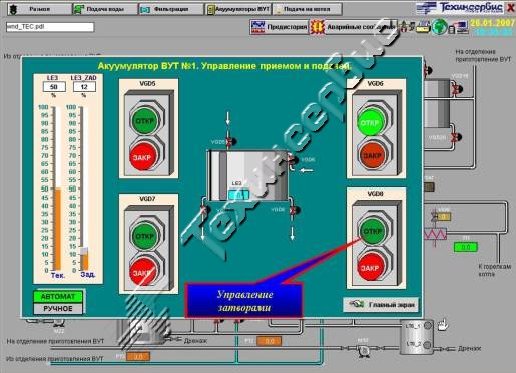

Operator's screen: coal grinding Operator's screen: CWF storage, filtering, filing

Conversion of existing boiler units to CWF does not require great rework of the boiler and high capital costs.

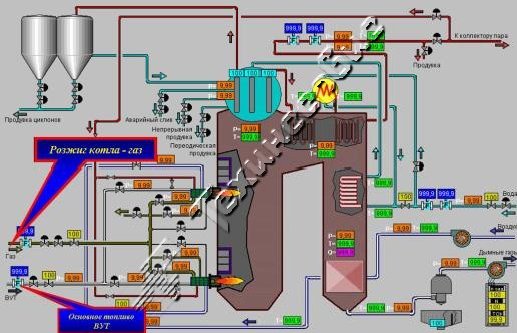

To reduce the zone of active combustion and reduce the temperature at the outlet from the furnace of the boiler, Techinservice has developed and patented a muffle burner for earlier evaporation of the moisture of a coal-water emulsion. The CWF sprayed flow enters the area of the furnace with a high degree of axial recirculation of flue gases. In the muffle burner there are two stages of twisting and two stages of gas distribution for heating the muffle and maintaining the front of ignition.

The muffle burner provides the opportunity for combustion in the boiler of two types of fuel (gas and coal-water fuel), both separately and in combination.

| Heat power of a burner (during operation with CWF) | MW | 12, 825 |

| Rated gas consumption | m3/h | 5000 |

| Rated coal-water fuel consumption | m3/h | 8,1 |

The processes of the CWF preparation and burning are fully automated.

Boiler with gas burners before reconstruction Conversion of the BKZ-50-39F boiler to the CWF combustion

Boiler. Screen of boiler operator. Main fuel of CWF

Boiler. Screen of boiler operator. Main fuel of CWF

Advantage of converting boilers to CWF using Techinservice® patented technology:

- having a higher reactivity and lower ignition temperature compared to the original coal, it determines a high degree of burnout of the combustible mass of fuel (the degree of burning of the combustible mass during CWF burning is 95-99%);

- reduces emissions of CO, SO2, NOX (included in the Kyoto Protocol

- does not belong to combustible and explosive substances, for this reason it is easily transported;

- for the production we can use coal of any fraction and caloric content, including coal slurry;

- the cost of 1Gcal obtained from CWF burning is lower than that of any other type of fuel;

- conversion to the CWF use does not require significant costs;

- if necessary, it is possible to use jointly CWF and other types of fuel - fuel oil, coal, gas;

- the use of CWF provides a reduction in heat loss with the flue gases due to lower temperatures of the gases in the furnace and a smaller excess of orderly supplied air, as well as the almost complete elimination of heat losses from chemical incomplete combustion;

- when water-coal fuel is combusted, the efficiency of boilers increases to 93-95% and depends little on their physical condition, thus ensuring high efficiency of the boilers;

- tanks in which CWFs are transported are easily cleaned from its residues, unlike oil-fuel tanks;

- in case of accidental spills, there is no damage to the environment.

CWF is suitable for use in both designed and already operated units instead of solid, liquid and gaseous fuels in thermal power plants, steam and hot water boilers.

years experience in the development of production projects

successful projects of different scale in Ukraine and abroad

Representative offices in Bulgaria, Czech Republic