Dehydration on zeolitic membranes

Dehydration on zeolitic membranes

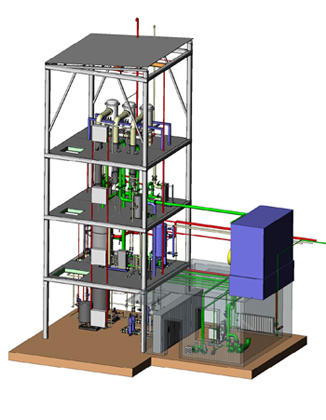

ALCOHOL DEHYDRATION STATION (BIOETHANOL PRODUCTION)

This station is an integral part of bioethanol production and can also be installed on board of an existing distillery. The final product of the distillery (alcohol: 96.4%) transfers to the heating and evaporation station, then the alcohol in the vapor phase goes to the dehydration station. The dehydration process is based on the principle of zeolite membranes (described below) presented in the form of ceramic tubes with zeolite sputtering.

Advantages of the proposed installation:

- the possibility of transferring the distillery to bioethanol production without significant reconstruction of the existing equipment;

- possibility to produce bioethanol with alcohol content of 99,8%;

- minimization of energy and operating costs.

Peculiarities of Zeolite Membrane Dehydration Plant:

This unit compares favorably with the column-based dehydration systems widely used in Europe. The proposed system is based on zeolite membranes which are ceramic tubes with zeolite sputtering.

The process of dehydration occurs in the following way: vapor phase (consisting of water and ethanol) transfers to intertube space of the dehydration set; water steam (the molecule size of which is less than pores of the selective membrane) goes through a ceramic tube with zeolite sputtering and is carried away by a vacuum pump, and ethanol vapor (the molecule size of which is more than pores of the selective membrane) goes out of the set and comes to the condenser of dehydrated ethanol.

The driving force of water vapor penetration through the zeolite membrane is a pressure difference between the tube space (created by a vacuum pump) and the inter-tube space (created by heating steam of the evaporator and the condenser of dehydrated ethanol).

The peculiarities of design and principle of operation of the proposed plant allowed to simplify considerably the dehydration process, to increase its efficiency and economy.

Advantages of the offered dehydration plant for alcohol (bioethanol production):

- extremely high degree of ethanol separation (due to high membrane selectivity);

- possibility of obtaining a high-quality product with an ethanol concentration of 99.8%;

- low operating costs;

- ease of integration into existing systems;

- rapid start-up and shutdown;

- easy and reliable automation and control;

- minimum downtime (due to low operating costs and lack of regeneration);

- easy installation and compactness of the plant;

- minimization of human factor influence on the overall process.

years of experience in developing production projects

successful projects of different scale in Ukraine and abroad

Representative offices in Bulgaria, Czech Republic