Biogas stations

Biogas stations

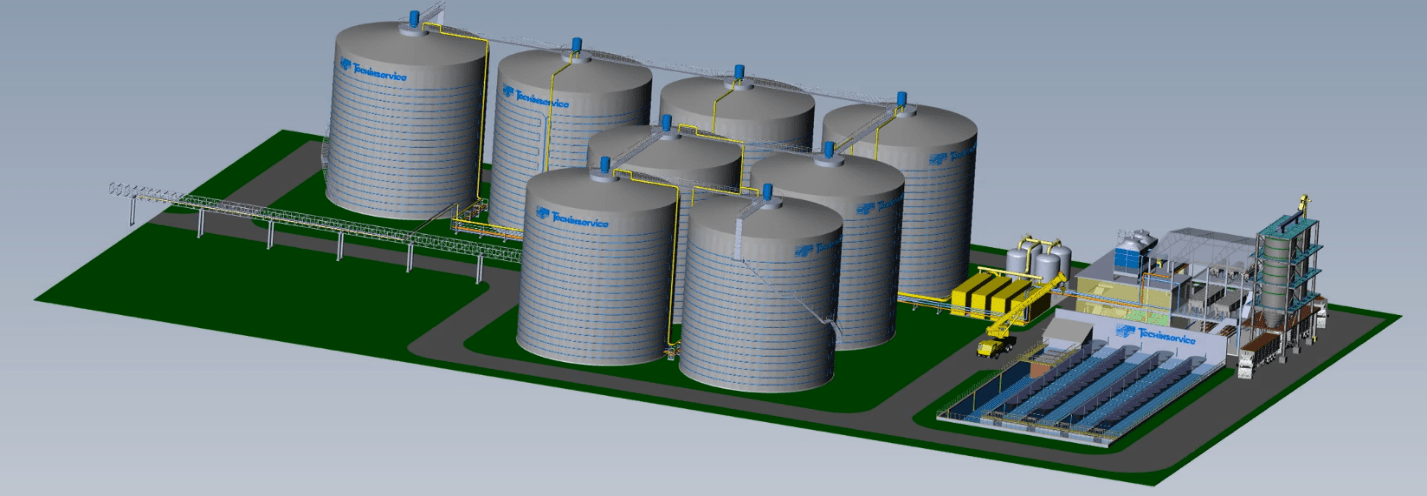

The biogas plant is based on thermophilic methane fermentation technology. Fermentation takes place in vertical fermenters.

The corn bard is pre-cooled to a temperature of +52C and pumped into the receiving tank of the biogas plant. Feedstock is loaded into the fermenters in portions using pumps. The substrate is moved in the fermenters at a stable temperature. The heating/cooling system is presented in the form of an external spiral heat exchanger, through which the substrate from the fermenter is pumped and circulated through one circuit, and the coolant circulates through the other. Depending on the temperature of the substrate, either heating or cooling of the substrate is provided inside the fermenter. Air-cooling units (ACUs) are installed to cool the substrate. In this way, a stable operating temperature of ±0.1 °C is maintained during the entire fermentation process. The fermenters operate in thermophilic mode. The substrate in the fermenters is periodically stirred by a vertical central stirrer. The stirrer drive is fixed outside the fermenter in the upper part of the floor and is always accessible for inspection and maintenance from the outside. The average fermentation time in the fermenters is 24 days. The spent fermented mass is removed from the fermenters by pumps and fed to the decanter section, where the substrate is separated into solid and liquid organic fertilisers. It is possible to return part of the squeezed digestate to the digesters. Solid fertilisers are unloaded into a bulk hopper for accumulation and quick shipment to trucks and transport off-site and can be used as organic fertilisers for fields, while the liquid leachate is sent for aerobic treatment. The biogas produced during the fermentation process rises up under the ceiling of the fermenters and is discharged through a pipeline to a separately located gas holder. The gas holder is designed as a two-layer dome and is mounted on a concrete base separately next to the fermenters. The first dome is an external protective film that provides protection against precipitation and damage from foreign objects. To prevent the pressure in the gas holder from exceeding the permissible pressure, it is equipped with a safety valve.

Part of the biogas can be fed into a boiler to generate steam to meet process needs or to generate electricity.

Biogas can also be purified for the production of biomethane for supply to the gas transmission network.

Biogas purification - biomethane production

Aerobic treatment of the filtrate-digestate

years experience in the development of production projects

successful projects of different scale in Ukraine and abroad

Representative offices in Bulgaria, Czech Republic