Articles

Extraction and processing of ethanol-containing products: modern solutions and developments of Techinservice

08.09.2014

O.G. Galuzinskiy, Head of the Department of Biotechnologies at Techinservice PG

V. P. Melnichuk, Production Engineer of Department of Biotechnologies of Techinservice MG

_______________

From the dawn of time mankind has been aware of ethyl alcohol primarily as the main component of alcoholic beverages. Except foodstuff, ethyl alcohol is widely used as a fuel as well as for production of premium gasoline and its high-octane number components (ethyl tertiary butyl ether). Ethyl alcohol also serves as a raw material for the production of many chemical products (acetaldehyde, diethyl ether, acetic acid, chloroform, ethyl acetate, ethylene, etc.), is widely used as a solvent (in the paint-and-varnish industry, in the production of household chemicals and many other fields), is a component of antifreeze and windshield washers, widely used in medicine, cosmetology and perfumery.

In connection with the industrialization and the search for alternative fuels, interest in ethanol as a fuel is growing steadily.

Only in the last five years the global production outputs of fuel ethanol have grown more than one-and-a-half times and in 2012 amounted to 106 mln cubic meters.

Based on this, 5 years ago when determining further development directions, Techinservice paid attention to the technology market for the production of ethanol-containing products. For the implementation of projects of this direction, on the basis of the engineering group of the company a department of biotechnology was created.

One of the main approaches of Techinservice when implementing engineering ideas has been and remains a comprehensive approach to the project implementation – from analysis and selection of a technology to its successful introduction.

Selection of raw materials

The configuration of the complex for the production of ethanol-containing products primarily depends on the type of raw materials being processed and on the method of its primary processing.

Techinservice offers comprehensive solutions for the processing of both sugar-containing (sugar beet, sugar cane, sweet sorghum, beet molasses, etc.) and starch-containing (wheat, corn, rye, barley, etc.) types of raw materials.

Criteria for selecting raw materials remain unchanged:

- cost;

- yield;

- output of target product;

- requirements for processing;

- year-round availability;

- requirements for growing, harvesting, transportation and storage;

- possibility of by-product processing (receipt of additional profit).

Comprehensive approach to the primary processing of raw materials

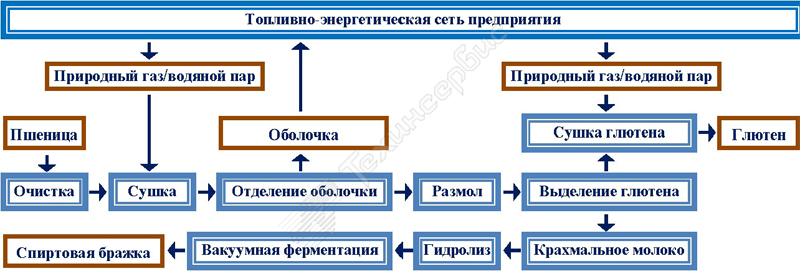

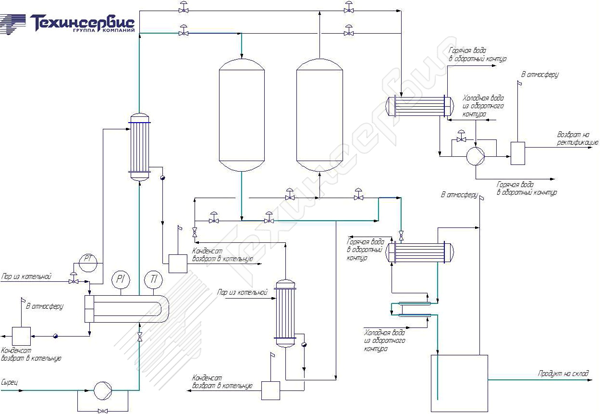

The comprehensive approach of Techinservice to the primary processing of starch-containing raw materials (wheat) can be demonstrated by the example of a basic project of the complex for deep processing of wheat into fuel ethanol and ETBE developed by our company (a flowchart of the technological process is shown in Fig. 1).

Fig. 1. Flowchart of the technological process of wheat primary processing

Fig. 1. Flowchart of the technological process of wheat primary processing

Among the processing methods used by Techinservice in this project, it is worth noting:

- Separation of wheat from shell

It is planned to separate wheat from shell in the amount of approximately 20% by weight of the processed wheat with a moisture content of 14%.

Advantages:

- reduction of the consumption of fuel and energy resources by the complex by 55% due to the use of detachable wheat shells as a solid fuel (lower heat value is approximately 3600 kcal/kg);

- possibility of obtaining a more transportable "mix" (a mixture of crushed wheat and water);

- reduction of power consumption for the transportation of products at the site of wheat primary processing due to removal of raw material components from the system which are not involved in the production of ethanol.

Disadvantages:

- insignificant loss of starch with a detachable shell (no more than 1% of the initial amount of wheat starch).

- Finely-ground wheat

One of the main factors of the high-quality separation of wheat components is the quality (fineness) of its grinding – the flour particle size before "mix" preparation should not exceed 250 microns. For the implementation of this task in Europe, as a rule, ultra-rotary mills are used, which are distinguished by the high cost of main and peripheral equipment as well as substantial operating costs. For the implementation of a similar task, Techinservice offers to use three-stage wheat grinding on the base of grain rollers and sifters with semi-products circulation (re-grinding of coarse-broken grain).

- Gluten separation

The separation of wheat gluten from the "mix" with its following washing from starch, drying and packaging is provided. This product with a mass content of vegetable protein of at least 70% is widely used in bakery products, pasta products and is also in demand in the meat-processing industry.

Advantages:

- possibility of obtaining an additional commercial product, which significantly reduces the payback period of the project and its investment attractiveness;

- possibility of obtaining a more transportable "mix" in the form of starch milk with an increase of the solids content in it up to 30% and a starch purity of 87%;

- reduction of power consumption for the transportation of products at the site of wheat primary processing due to removal of raw material components from the system which are not involved in the production of ethanol.

Disadvantages:

- substantial energy intensity of the process (approximately 360 kW of electrical and 2,000 kW of heat energy per 1 ton of commercial gluten).

- Vacuum fermentation

The separation of the wheat shell and gluten from the "mix" allows obtaining a transportable wort (starch milk) with a solids content of up to 30%. Fermentation of the wort with such a high solids content is implemented through the vacuum fermentation technology, which allows obtaining an alcohol mash with an ethanol content of up to 19% by volume. The existing technologies of vacuum fermentation require the creation of fermentation units operating under vacuum, this increases their metal consumption and as a consequence their cost. The existing vacuum fermentation technologies also require energy-intensive compressor units for pumping the entire volume of carbon dioxide produced during fermentation.

Techinservice offers an alternative approach to the implementation of the vacuum fermentation process. The essence of Techinservice know-how is that the cooling process of the fermentative volume (maintenance of the optimum temperature in conditions of the release of excess heat) is organized due to boiling up of the fermentative mass (mash) circulating through the vacuum chamber and the fermentative mass overheated relative to the temperature of the saturation line which is under negative pressure of -0.95 bar (excess).

Advantages:

- possibility of obtaining spirits mash with an average volume ethanol content of up to 19% and, as a result, a reduction of heat energy consumption by 25% when processing spirits mash in the mash-rectification house;

- possibility of organizing the fermenting process in the range of optimum ethanol content in the fermentative mass at the level of 9% by volume (the absence of the inhibitory effect of alcohol on the vital activity of alcoholic yeast);

- possibility of obtaining flash condensate of the fermentative mass with a volume content of ethanol up to 40%, that makes it possible to reduce the cost of heat and electrical energy during its processing in the mash-rectification house.

Disadvantages:

- additional energy costs in comparison with the classical fermentation process (approximately 0.1 kW per 1 liter of absolute ethanol).

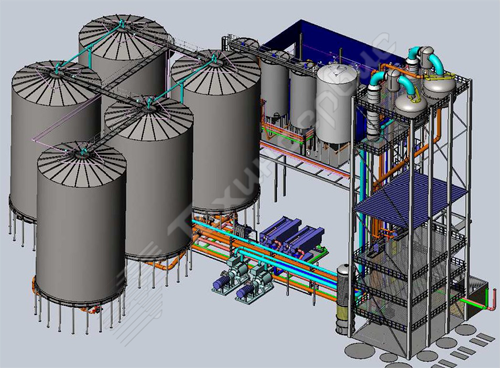

Fig. 2. Layout of the processing equipment of the vacuum fermentation area

Fig. 2. Layout of the processing equipment of the vacuum fermentation areaEnergy-saving distillation, rectification and dehydration

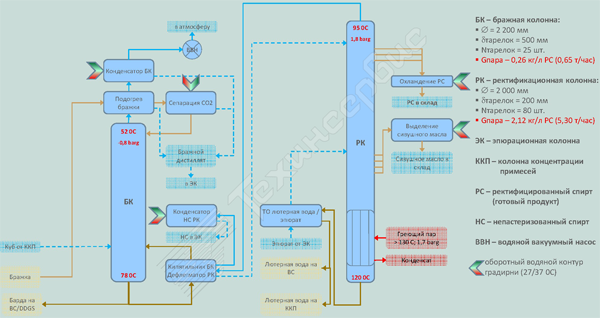

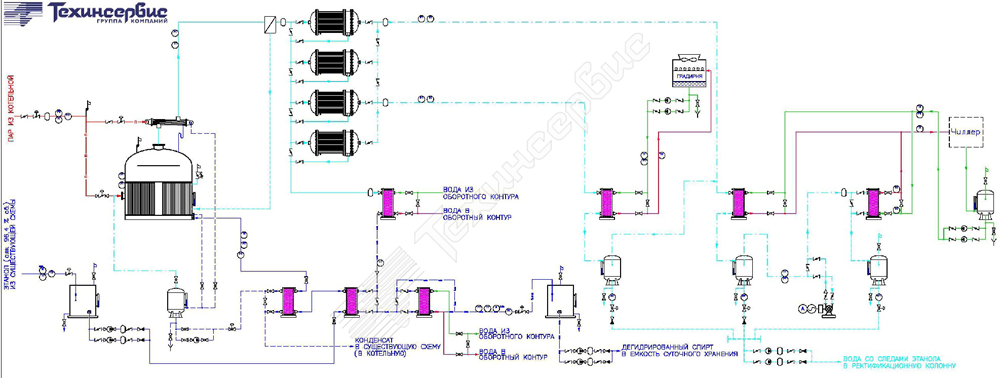

Schematic piping diagram of the distillation-rectification column which heats the mash column is shown in Fig. 3.

It should be noted that the distiller produced by Techinservice can use process steam of a relatively low potential (up to 2.5 bar (excess)), which makes it possible to organize heating of the distiller with secondary steam of the evaporating station for condensing distillery dregs operating under pressure. This approach was used by Techinservice in the project of production of potable alcohol of premium class for one of the spirits distilleries of the Republic of Bulgaria.

Fig. 3. Schematic piping diagram of the distillation-rectification and mash columns

Fig. 3. Schematic piping diagram of the distillation-rectification and mash columnsThe column equipment of the distiller manufactured at the engineering base of Techinservice is equipped with high-performance contact devices – improved valve trays (IVT). IVT has a wide range of reliable and efficient use in columns:

- with a diameter from 800 mm to 10,200 mm;

- with number of trays from 1 pc. to 200 pcs.;

- with a distance between trays from 100 mm to 1,100 mm;

- operating both under vacuum and under pressure.

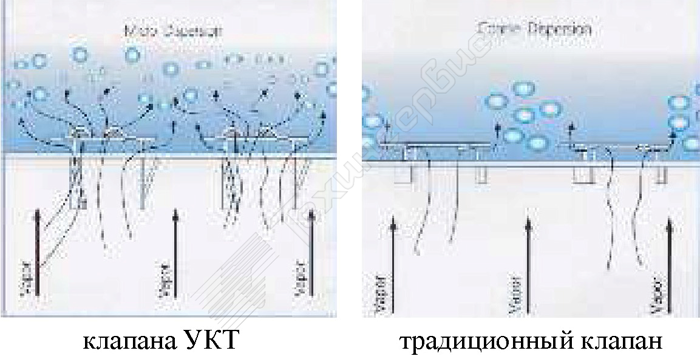

- the design of IVT provides a mechanism for the flow movement in the valves, excluding stagnation of liquid and ensuring its uniform movement, and also increasing the density of bubbles throughout the bubbling area (fig. 4);

- formation of sediment on the IVT surface is excluded, which leads to an increase in its service life;

- "dead space" (stagnant zones) is excluded in the places of fastening the panels of the tray as a result of the use of active connections of IVT, which leads to increased performance and efficiency of the tray (fig. 5);

- use of the active connection of IVT reduces the installation time of the tray by 30-50%;

- design of IVT allows reaching the smooth control of the column equipment operation in a wide range of performance.

Fig. 5. Bubbling of the active connection of IVT and bolted connection of the standard tray

Fig. 5. Bubbling of the active connection of IVT and bolted connection of the standard tray

Ethanol dehydration

The ethanol dehydration site is an integral part of the technological process for the production of fuel ethanol and the production of high-octane components based on ethanol (ethyl tertiary butyl ether). When ethyl alcohol is used as a raw material for the production of chemical products, its dehydration is a necessary step of the technological process.

The most common commercial methods of ethanol dehydration are:

- azeotropic rectification;

- molecular sieve adsorption;

- membrane dehydration.

The last two of these methods are the most progressive and cost-effective, whose operation is based on the use of zeolites.

Zeolites (from the Greek ceo lit – boiling stone) are aluminosilicates which contain oxides of alkali and alkaline earth metals in their composition and are notable for well-defined regular pore structure which are filled with water molecules under natural temperature conditions. If water is removed from the pores of zeolites, they can be refilled with water or another liquid. The reversibility of the process of hydration and dehydration of zeolites determines their use in the processes of drying, purification and separation of liquids. Zeolites absorb substances into their adsorption pores. But not all substances can penetrate and stay there. This is explained by the fact that the adsorption pores are interconnected by pores of a certain size. Only those molecules whose critical diameter is smaller than the diameter of the pore can penetrate the pores.

Synthetic zeolites of the NaA brand which adsorb most industrial gases, the critical size of whose molecules do not exceed 0.4 nm (including water vapor), found the best industrial application.

Molecular sieve adsorption

Fig. 6. Schematic diagram of ethanol dehydration proposed by Techinservice according to the technology of molecular sieve adsorption

Fig. 6. Schematic diagram of ethanol dehydration proposed by Techinservice according to the technology of molecular sieve adsorptionWater-alcohol vapor from the distillation-rectification column is fed for dehydration. In the case of increased pressure vapor passes through one of the adsorbers. The water molecules which are contained in vapor are retained in the pores of the molecular sieves, and dehydrated ethanol leaves the adsorber. Dehydrated ethanol is condensed, cooled and discharged into the collection tank. When the molecular sieves are saturated with water in the first adsorber, the operation of which is controlled by the water content in dehydrated ethanol, water-alcohol vapor is supplied to the second adsorber. When the second adsorber is used, vacuum is generated in the first adsorber with the help of a vacuum pump (through a condenser). Due to the change of the medium boiling points in the adsorber in the case of significant pressure change, evaporation of water held by molecular sieves takes place. To prevent significant cooling of the molecular sieves in the first adsorber during water evaporation, some vapor of dehydrated ethanol after passing through the second adsorber overheats and returns to the first adsorber. Water-alcohol vapor, which leaves the first adsorber, is condensed, discharged into the collection tank and returned to the distillation-rectification column for processing. During the operation of the second adsorber, the regeneration of the molecular sieves takes place in the first adsorber. After that, the supply of water-alcohol vapor from the distillation-rectification column is carried out to the first adsorber again, and the second adsorber is transferred to the mode of regeneration under vacuum, and the cycle repeats.

Currently the described above process is the most common method of ethanol dehydration in the world. In 2002, Techinservice implemented this technology at one of the distilleries in the Czech Republic (still operating today). At the same time, for now, the technology is considered to be outdated, and the frequency of operation, the presence of regeneration and the high level of operating and energy costs have led to the development and implementation by Techinservice of other more advanced dehydration methods.

Membrane dehydration

The NaA zeolite membrane is used for dehydration of various media, including ethanol. In the case of a process in the liquid phase, the process is called pervaporation and in the case of a process in the vapor phase, the process is called vapor permeability.

The zeolite membranes are used in the form of a thin layer applied on a ceramic base, which makes it possible to conduct the process with large flows. On a commercial scale, it is preferable to apply a zeolite layer on the inner surfaces of ceramic elements (tubes) in order to avoid mechanical damages and ensure an optimal flow. Zeolites of the NaA type in the form of membranes can be applied on tubular bases, represented by single-bore or multi-bore tubes.

The use of zeolite membranes allows conducting the dehydration process at the higher parameters (pressure is 5.5 bar (excess) and temperature is 135 °C), which has a beneficial effect on the metal intensity of the installations.

The dehydration equipment, based on the use of zeolite membranes, due to its high selectivity, reliability and durability, surpasses the existing analogues: molecular sieves and polymeric membranes.

It should be noted that at its own engineering base Techinservice serially produces the whole range of the specific processing equipment included in the ethanol dehydration complexes, operated both according to the membrane dehydration technology and the molecular sieve dehydration technology or azeotropic distillation.

Schematic diagram of ethanol dehydration according to the membrane dehydration technology proposed by Techinservice is shown in fig. 7.

Fig. 7. Schematic diagram of ethanol dehydration according to the membrane dehydration technology proposed by Techinservice

Fig. 7. Schematic diagram of ethanol dehydration according to the membrane dehydration technology proposed by Techinservice

Water-alcohol vapor is fed from the distillation-rectification column to the intertubular space of the membrane module for dehydration. Water vapor, the size of the molecules of which is less than the pores of the selective membrane, passes through a zeolite-coated ceramic tube and is carried away by a vacuum pump. Ethanol vapors, the size of the molecules of which is larger than the pores of the selective membrane, leave the unit and enter the dehydrated ethanol condenser. The moving force of the penetration of water vapour through the zeolite membrane is the pressure difference between the tube side (created by a vacuum pump) and the annular space (created by the heating vapour of the evaporator and the condenser of dehydrated ethanol).

The process described above does not require regeneration and is characterized by a high efficiency and, as a result, has the lowest operating and energy costs. Within the framework of the state program for the reconstruction of the alcohol industry in Ukraine, in 2008 Techinservice implemented this process at five spirits distilleries in Ukraine. The total project capacity is 125 ths. tons of fuel ethanol per year.