2014 Projects

Biopharma Pharmaceutical Mill (Bila Tserkva, Ukraine)

31.12.2014

Having more than 20 years of experience in the field of automatization of production processes and engineering systems for different industries Techinservice Intelligence has developed and implemented complex automation system with process control and new engineering infrastructure for Biofarma pharmaceutical plant (Bila Tserkva town, Ukraine).

Monitoring and automation systems have been implemented into two buildings – production and laboratory.

Monitoring system constantly collects the information from primary sources (temperature and pressure gauges, etc.) displays it in a user-friendly form, records and stores all abnormal deviations.

Automation system monitors and controls technological areas of production, as well as the life support system of the buildings.

Monitoring and automation systems of a new pharmaceutical plant Biofarma include several technological areas:

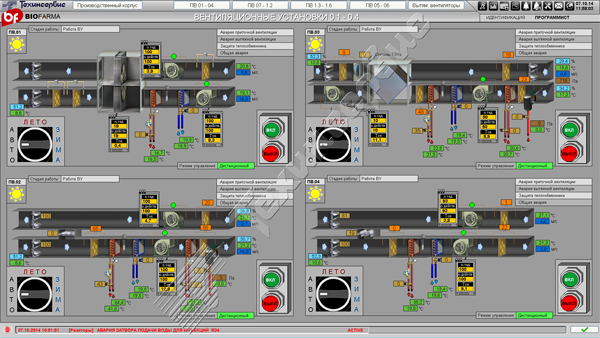

1.Ventilation and air conditioning system

Comprises of 14 air handling units of the production facility and 11 AHU of the laboratory building. Additionally, there are 23 air exhausters of the buildings.

Mnemonic control scheme of the ventilation and air conditioning system

Mnemonic control scheme of the ventilation and air conditioning system

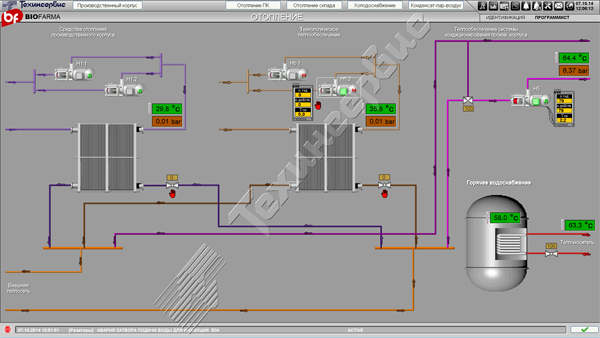

2.Individual heating unit

Control system of the individual heating plant is designed to manage pumps feeding the heat transfer fluid to the heating, air conditioning and process heat supply systems. It also controls operating mechanisms to keep the temperature of the heat transfer fluid in the set range. The plant has heat supply units automatized for production facility, laboratory building and warehouse.

Mnemonic control scheme of the heating system

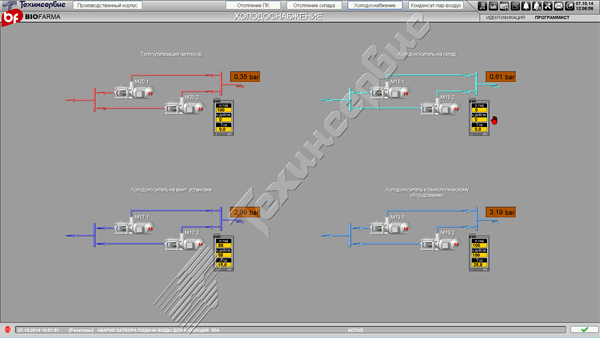

3.Refrigeration

Automation of the refrigeration system ensures the necessary pressure in the cold supply systems for the process sections.

Mnemonic control scheme of the refrigeration system

Mnemonic control scheme of the refrigeration system

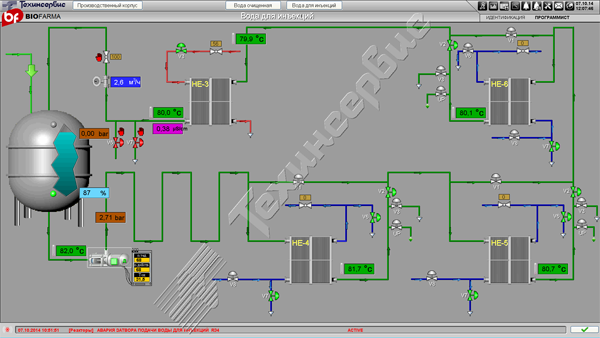

4.Water treatment

Automation system of water preparation controls water feed pumps to the circulation circuit, keeps the necessary temperature in the circuit, controls make-up of water in the tanks and water treatment for end users. Automation system of water for injection and purified water treatment has been introduced at this factory.

Mnemonic control scheme of the water for injection and purified water treatment

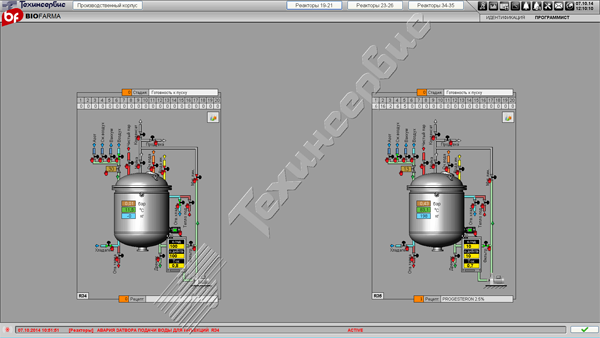

5.Reactor

At the factory is implemented an automation system of the reactors where medicinal components are blended to produce the end product. Feeding, mixing and unloading are done automatically due to the control of the operating mechanisms. Product feeding and mixing processes are done by preset recipes.

Mnemonic control scheme of the reactors

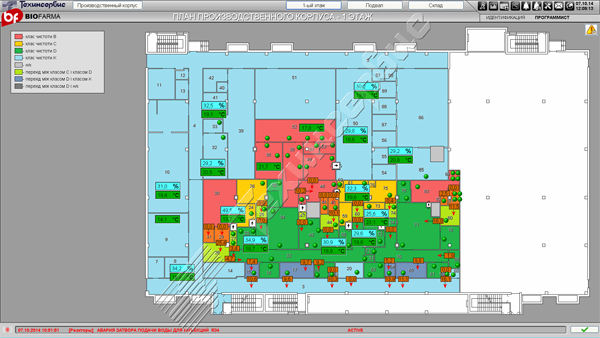

6.Microclimate

Automation system controls the temperature, humidity and pressure changes in the clear areas of the production facility and laboratory. The system gives alarm and pre-alarm messages if monitored parameters have passed the specified boundaries and prepares end-of-day reports.

Mnemonic control scheme of the microclimate system

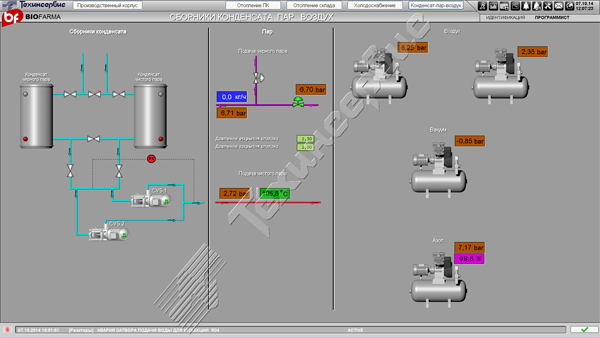

7.Air, vacuum, nitrogen.

Control of the technological parameters (compression, rarefaction etc.) of compressor station, vacuum-pumps and steam from the boiler house.

Mnemonic control scheme of the operational parameters of Biofarma pharmaceutical plant

Monitoring and automation systems developed and implemented by Techinservice at Biofarma pharmaceutical plant have allowed reaching the following economically profitable attributes:

- • energy saving (electricity, heat, water and gas);

• reduction of maintenance personnel;

• reduction of expenses for maintenance, repair works and replacement of the engineering equipment;

• reduction of damages from incidents due to the prevention and timely detection;

• increase of operational life of the equipment due to the track of hours in operation and its equal distribution;

• less service contracts due to the reduction of service works because of the constant control and registration of working parameters of equipment;

• improved reliability of the engineering systems on account of using automation equipment from a single vendor;

• options for expanding in the future;

• options for association of several systems;

• availability, ease of use, relaxation in the requirements of the engineering level of the personnel;

• possibility to stay within the electricity consumption limits;

• prompt detection and troubleshooting;

• increase of the comfort level and security inside of the building.

years experience in the development of production projects

successful projects of different scale in Ukraine and abroad

Representative offices in Bulgaria, Czech Republic