2013 Projects

Buinsk sugar factory (Tatarstan)

15.12.2014

Techinservice has been directly involved in modernization and reconstruction of Buinskiy Sugar Mill, the largest food processing enterprise of the Republic of Tatarstan.

Techinservice has built "from scratch" a new sugar end of the plant in record-breaking time in order to ensure the capacity of the plant up to 7,000 tons of beet per day.

The whole cycle of construction and supply of equipment for the sugar end was 4 months.

The customer was provided with a unique solution, taking into account all its requirements and specifications. Techinservice due to availability of its own production and installation base (GMZ), design and software departments, built a new sugar end "from scratch" in just 4 months. All equipment was developed and produced by Techinservice, except for centrifuges. The power capacity of the sugar end will enable to increase the capacity of the plant up to 7 ths. tons of beet per day. For this purpose all the necessary equipment was supplied and Buinskiy Sugar Mill was able to reduce the costs for further modernization. We are always ready to provide extremely effective solutions for our customers. We can say for sure that it is possible to build the sugar end "from scratch" in 4 months.

Area for construction of the sugar end (10.05.2013)

Area for construction of the sugar end (10.05.2013)

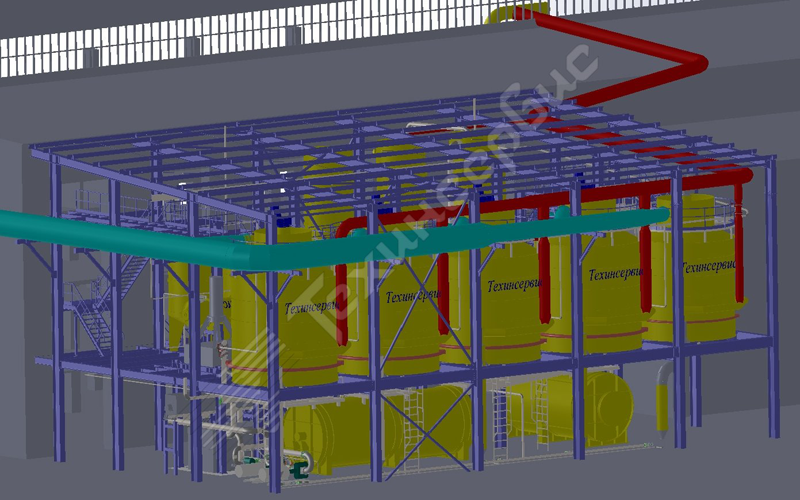

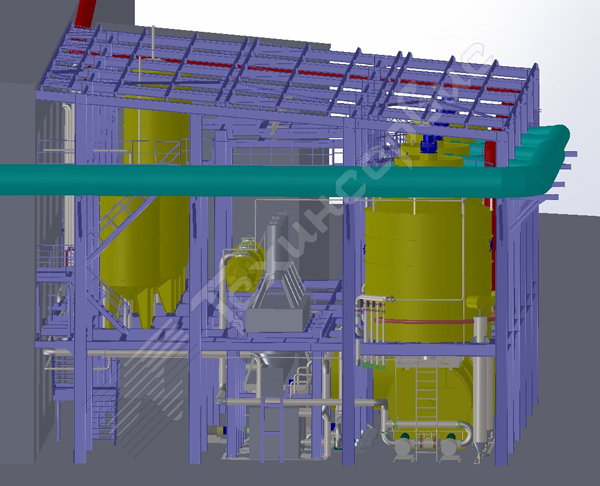

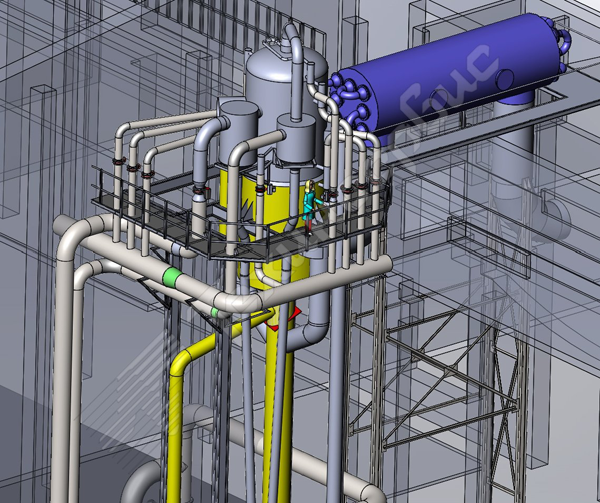

For a more detailed study of the layout of the equipment a multiple-vector 3D design of the object was made, which allowed to develop the high-quality design documentation quickly and accurately.

3D model of the sugar end – front view 3D model of the sugar house – side view

Simultaneously, production and supply of the equipment from the warehouse of Grebenky Machine Building Plant (GMZ™) were carried out.

Start of installation (17.05.2013) Installation of the first equipment – Massecuite receiving mixer (03.06.2013)

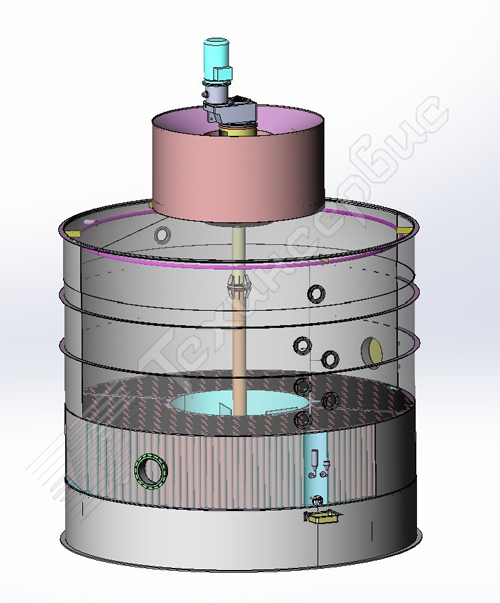

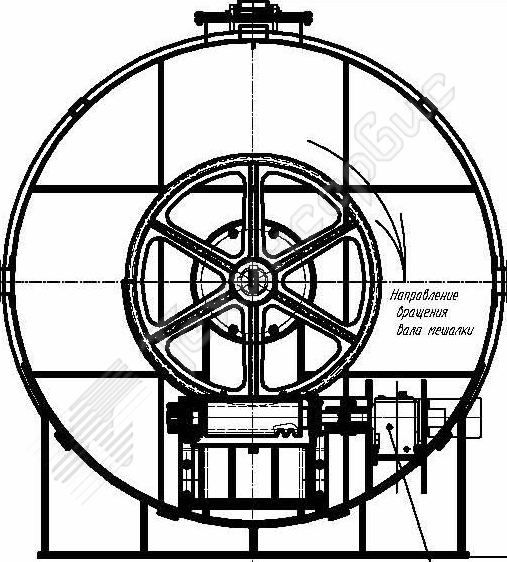

As it is known, the vacuum pans installed in the sugar end are of key importance because the quality of sugar depends on their operation.

Techinservice manufactured and supplied four high-performance ТВА-75 vacuum pans and one ТВА-60 vacuum pan (for seed massecuite). These vacuum pans have a large specific heating surface, which allows to obtain high-quality commercial sugar and help to achieve good energy performance of a sugar plant.

3D model of the vacuum pan

3D model of the vacuum panA distinctive feature of these vacuum pans is a modular design principle, which makes it possible to transport the vacuum pans by vehicles to their destination without limitation in size.

In addition, this principle gives advantages when installing the vacuum pans at the operating enterprise, this was once again successfully tested at Buinskiy Sugar Mill.

Installed vacuum pans (15.07.2013)

Installed vacuum pans (15.07.2013)

The installed massecuite distribution unit of Series ТУР4 produced by Techinservice is designed for massecuite distribution for 3 centrifuges. Special mention can be made of the main advantages of this unit as simple installation and convenient maintenance, high performance with low power consumption and optimized structure design which ensures a compact installation of the unit in a small area.

3D model of the massecuite distribution unit

3D model of the massecuite distribution unit

All project documentation, including installation plans, can be quickly and without any errors obtained from 3D models of the equipment under development. And this, of course, helps to speed up the process of project implementation.

Part of the installation plan of the massecuite distribution unit

Part of the installation plan of the massecuite distribution unit

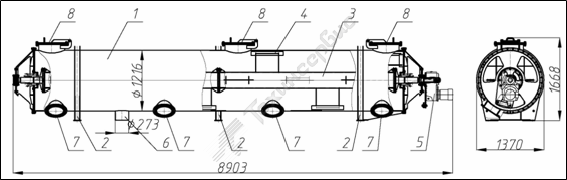

A ТМУ90 massecuite receiving mixer designed for 90 tons of massecuite was also installed. All massecuite receiving mixers produced by Techinservice are notable for the reliable structure which is achieved due to the manufacture of stainless steel of parts which are in contact with the product, and the quality sealing of the mixer shaft passages minimizes the occurrence of any leakages.

Shipment of the massecuite receiving mixer from Buinskiy Sugar Mill (16.05.2013)

Massecuite receiving mixer

Massecuite receiving mixer

According to the design decision of Techinservice, a ТТШ-50 sugar auger with a capacity of 50 tons of sugar per hour was supplied. This auger has the following advantages over the traditional vibrating conveyors:

- less metal-consuming;

- the design of the closed type (prevents ingress of foreign objects in the sugar);

- a lower degree of grinding of sugar crystals (at outlet there is the higher quality product).

It is installed above the substandard sugar melting mixer.

Sugar auger and substandard sugar melting mixer.

Sugar auger and substandard sugar melting mixer.

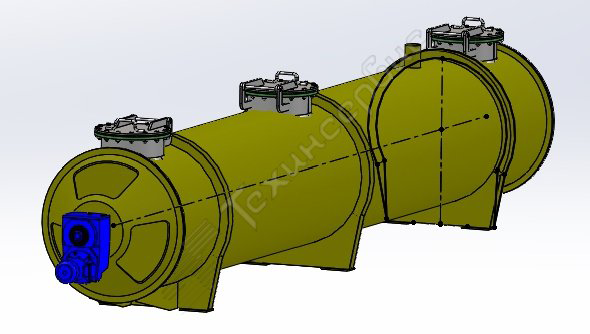

The main technical and economic indicators of the operation of the vacuum condensing unit and three fan cooling towers with a modernized water distribution system are:

• reduction of boiling time;

• minimal water consumption and, as a result, an increase of the environmental friendliness of the facility as a whole;

• ensuring the plant capacity up to 7,000 tons of beet per day.

The specified advantages of the condensers are determined by their original design scheme as well as the availability of the modern automatic control system.

Vacuum condensing unit before dismantling (28.05.2013) 3D model of the vacuum condensing unit Installed vacuum condensing unit (15.09.2013)

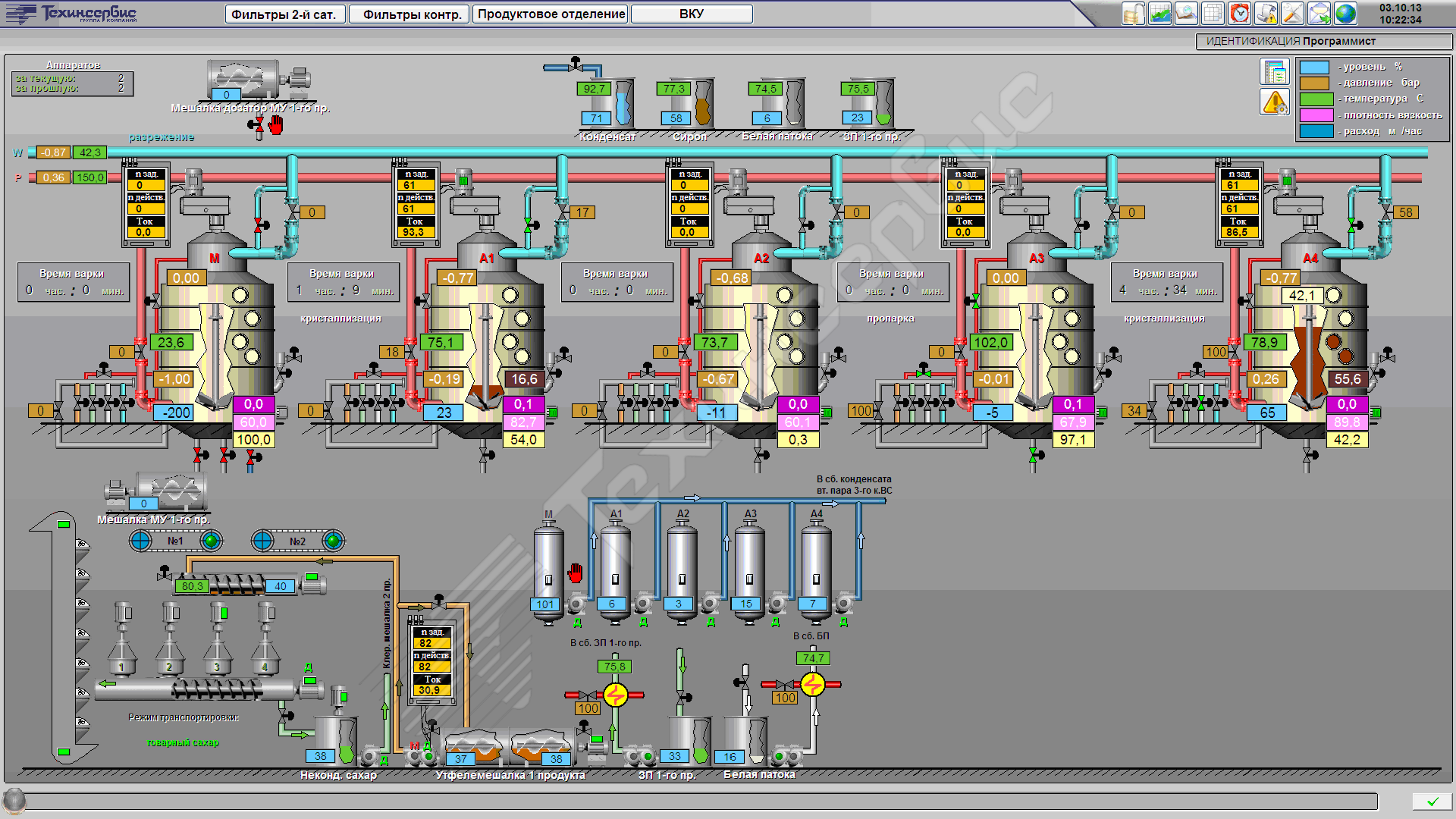

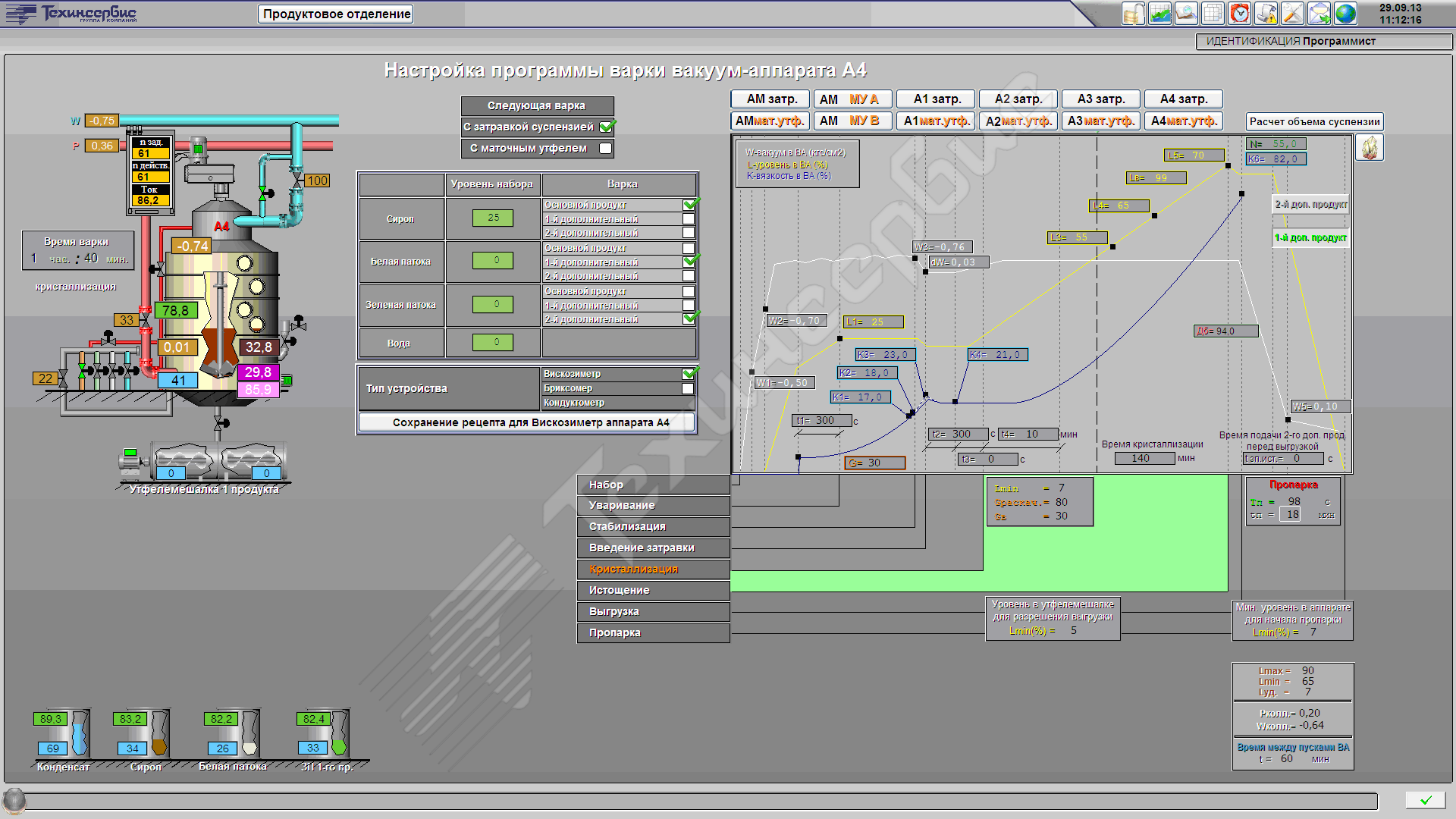

To achieve the most economical and efficient operation of the new sugar end at Buinskiy Sugar Mill, Techinservice developed and implemented the Topaz automatic control system of the sugar end.

General mnemonic control scheme of the vacuum pans

General mnemonic control scheme of the vacuum pans

General mnemonic control scheme of the vacuum pans

• sizing the main sugar fractions (allows to set boiling to a specific crystal size depending on the sugar market conditions);

• setting boiling time of the vacuum pans;

• auto-start mode of the vacuum pans (allows smoothing peak loads of steam consumption);

• automatic control of the crystallizing unit by maintaining a temperature balance between massecuite and cooling water in it which ensures better crystallization effect and, as a result, an increase of sugar output;

• full control and monitoring of the peripheral operation parameters of the sugar end:

1. regulation of the concentration of prepared remelts;

2. maintaining the required temperature of runoffs and molasses;

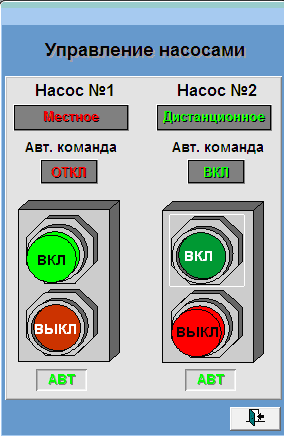

3. control of continuous and batch centrifuges;

4. control and alarm of pumps operation;

5. recording of process parameters and accumulation of information for a given period of time;

6. ability of remote control of system regulators from the operator's panel or computer keyboard (graphical mnemonic schemes provide visual information about the technological process status, the state of the mechanisms, operating modes and emergency).

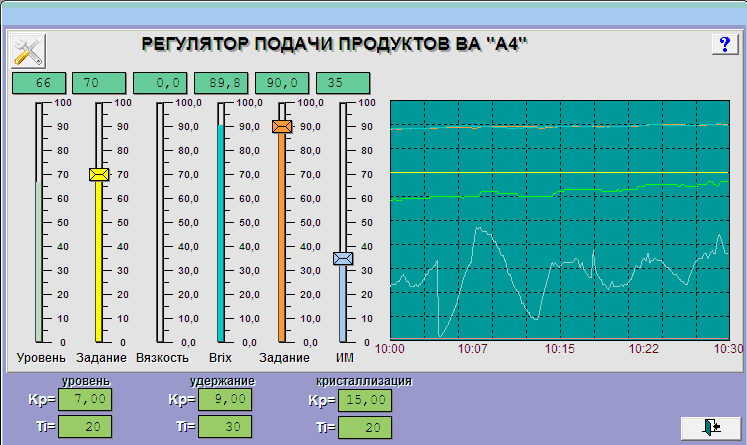

Mnemonic scheme of the boiling settings of the vacuum pans Controller of products feeding to the vacuum pan

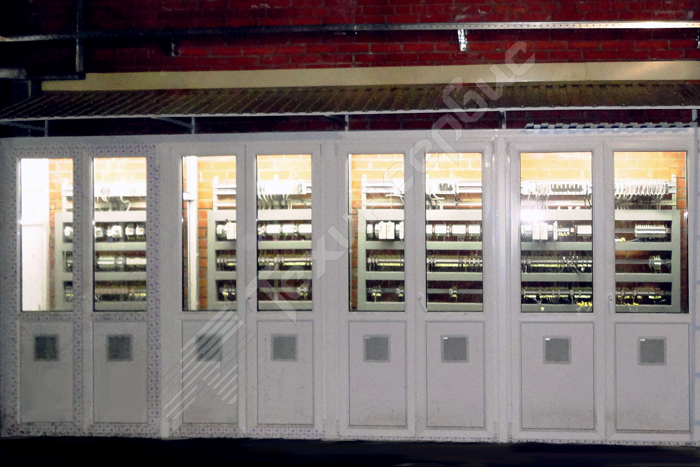

One of the main criteria of operation of this control system is the high survivability of the system (i.e., fail-safety of the control system in the case of failure of some devices). For this purpose several control points are provided:

- operator's room with workstations;

- operator's panels directly near the vacuum pans;

- pneumatic control panel.

Control center of the new sugar end of Buinskiy Sugar Mill (20.09.2013)

Control center of the new sugar end of Buinskiy Sugar Mill (20.09.2013)

New sugar end of Buinskiy Sugar Mill (20.09.2013)

New sugar end of Buinskiy Sugar Mill (20.09.2013)

years experience in the development of production projects

successful projects of different scale in Ukraine and abroad

Representative offices in Bulgaria, Czech Republic